Ok Al and everyone else.

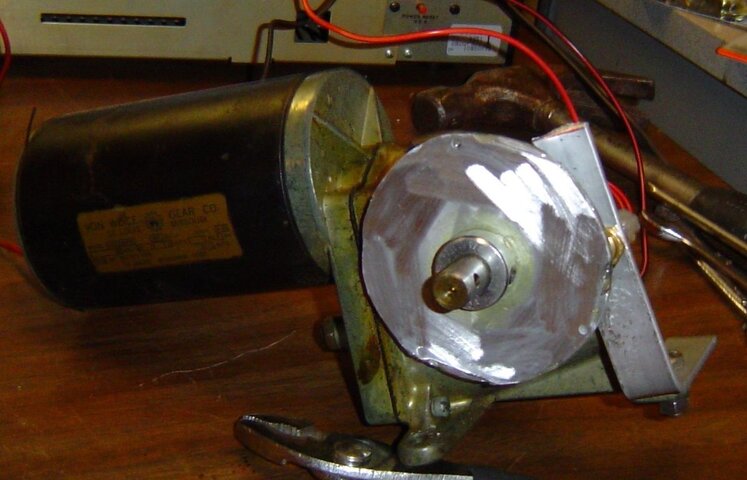

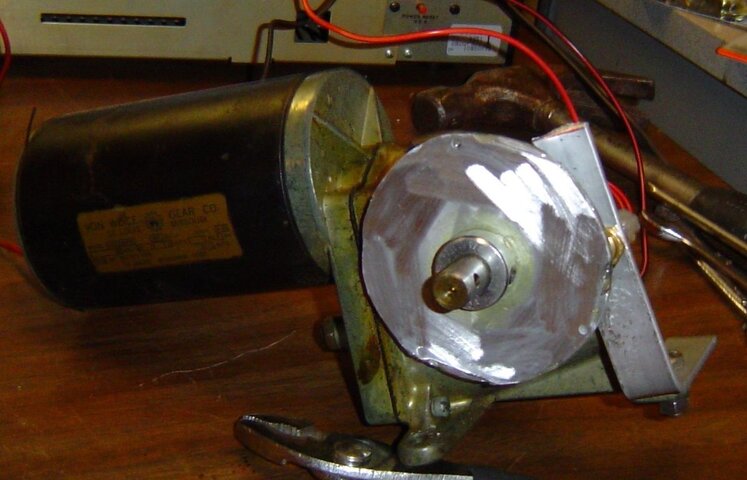

The finished product pictures as promised. There are a bunch of them and I tried to put them in order.

To make one exactly like the above model, you will need:

2 - 1/16" X 3-1/4" dia round aluminum plates.

1 - 1/2" locking collar (good quality that is the same dimension all around)

24 - 1/4" dia X 1/8" thick strong magnets

1 - 3/8" X close brass pipe nipple (package labled it 1/8", but package was wrong) 1/4" ID so whatever it is?

2 - 3/8" brass nuts (takes a 9/16" wrench)

1 - cylinder/plunger type non-biased reed sensor switch

1 - 1/8" X 3/4" aluminum bar stock (bend to fit)

1 - Bottle Contact Cement

1 - Tube Epoxy

I drilled 24 - 1/4" holes spaced evenly around the outer perimeter of the front piece. Yes I had to reem out the holes a little to get the magnets to fit in. Drill a 1/2" hole in the dead center of both pieces (again reem out just a little). Sand the plates a little to create good sticking surfaces, then chemically clean with alcohol and cement the two plates together. Next, cement the locking collar to the back plate and allow all to dry for at least an hour.

Lay out the magnets on a flat table far enough apart so they don't all jump together in a cylinder.

Put contact cement in every other hole with a tooth pick sparingly. Place the magnets with the side up that will be placed in the holes. Apply contact cement onto the magnets. Allow both surfaces to dry at least 10 minutes.

Insert the first twelve magnets in the glue applied holes making sure they all have the same polarity. Allow to dry for at least an hour.

Repeat for the final twelve magnets and holes, but make sure these magnets have the opposite sides facing up for the glue. The goal is to have 12 magnets pulling and 12 magnets pushing in every other hole. Allow to dry for another hour. You might even want to let it stand over night.

I made an outer ring of masking tape and an inner ring of masking tape to hold the epoxy in a channel while I spread it over the magnets and onto the plate. That will help you attain the correct thickness of the epoxy. Just a very thin layer over the top of the magnets.

When dry enough after about 2 hours, I pulled the tape off and used small side cutters to trim the excess epoxy from the sides of the channel.

Drill your holes in the aluminum bar stock. One for the mount bolt, and one for the brass switch holder. Put the switch holder in place and slide the locking collar/plate/magnet assembly into place and insert the switch into the brass switch holder. Line everything up where it needs to be to give you between 1/16" and 1/8" clearance between the switch and the magnets, then gently pull the locking collar/plate/magnet assembly off and epoxy the switch into the brass switch holder. As you can see, I made a hot glue glob on the wires at the end of the switch and applied epoxy to the switch and allowed it to spill over onto the hot glue. The hot glue glob is to give some stability to the wires coming out of the switch.

When all the glue is set, assemble and enjoy the benefits of your labor.

Estimated costs:

24 - magnets was $12.00 retail

1 - locking collar was $1.00 retail

1/16" - aluminum plate to make the two circles $5.00? I had them and didn't have to buy them.

Brass nipple and nuts - $2.00 retail

bottle of contact cement - $3.00 retail

tube of epoxy - $4.00 retail

reed sensor switch if all assembled like the one above, about $5.00 ( I had one, and didn't have to buy) If anyone orders these from Digi-Key, they have a $20.00 minimum for an order. Put me down for at least one and maybe two, and I will re-imburse you plus shipping for them.

Total costs if you bought everything would be approx. $32.00.

Some of my prices above are guess-timates and probably are a lot less than I have listed. Some of the stuff you might already have too. Glue and epoxy were costly, and I have enough left over for another 3 or 4 of these. Same with the aluminum bar stock.