10' CM Perf on AJAK H180

- Thread starter Magic Static

- Start date

- Latest activity Latest activity:

- Replies 138

- Views 23K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

"simple" way to double the count?

Let us know how that works out.

I would try for 20, to double the existing count, but any increase is good.

My magnets may be smaller, should we want to shoot for 30.

Edit: just saw your picture. If you get the double-count trick to work, we'd be done. :up

You and I talked on the phone, via text message, and via PM here on the forum.

I also PM'd Pendragon , since he's running at least one Ajak 180.

I was trying to promote an idea you gave me: two reeds in quadrature.

Basically, glue another reed to the existing housing.

Position it so it closes and opens half way between clicks of the original reed.

Now, just run one more wire back to a modified Vbox.

(this avoids having extra electronics at the motor)

In his Birdview thread, Pendragon mounted an exclusive-or (XOR) gate next to his shaft encoder on the worm gear.

The encoder put out two signals in quadrature, and the XOR gate combined them, doubling the count.

Anyway, I thought that might give the biggest bang for the least fabrication, and I wanted other forum members to have something to think about.

I'm getting a blown up Vbox from another member.

Even though it may be beyond repair, it -might- be a good test bed for the XOR mod.

Let us know how that works out.

I would try for 20, to double the existing count, but any increase is good.

My magnets may be smaller, should we want to shoot for 30.

Edit: just saw your picture. If you get the double-count trick to work, we'd be done. :up

You and I talked on the phone, via text message, and via PM here on the forum.

I also PM'd Pendragon , since he's running at least one Ajak 180.

I was trying to promote an idea you gave me: two reeds in quadrature.

Basically, glue another reed to the existing housing.

Position it so it closes and opens half way between clicks of the original reed.

Now, just run one more wire back to a modified Vbox.

(this avoids having extra electronics at the motor)

In his Birdview thread, Pendragon mounted an exclusive-or (XOR) gate next to his shaft encoder on the worm gear.

The encoder put out two signals in quadrature, and the XOR gate combined them, doubling the count.

Anyway, I thought that might give the biggest bang for the least fabrication, and I wanted other forum members to have something to think about.

I'm getting a blown up Vbox from another member.

Even though it may be beyond repair, it -might- be a good test bed for the XOR mod.

I installed the 16 count wheel. The stock counter was confused and skipping counts. The VBox didn't care, just kept crankin on' Installed the larger read swich, the counts were stumbled and skipping, the VBox kept on turning. I installed the small switch and bingo! 16 counts per revolution. The VBox can't keep up and keeps stopping and starting But doesn't miss a count. I noticed the VBox X has some weird responses to an empty AJAK with stock sensor. Stops and starts a lot, but put a load on it and it keeps right on chuggin. I'll have to swap it for the other one I have and see if still does that.

I installed the 16 count wheel. The stock counter was confused and skipping counts. The VBox didn't care, just kept crankin on' Installed the larger read swich, the counts were stumbled and skipping, the VBox kept on turning. I installed the small switch and bingo! 16 counts per revolution. The VBox can't keep up and keeps stopping and starting But doesn't miss a count. I noticed the VBox X has some weird responses to an empty AJAK with stock sensor. Stops and starts a lot, but put a load on it and it keeps right on chuggin. I'll have to swap it for the other one I have and see if still does that.

Last edited:

I'm getting a smoked Vbox X from Lone Gunman.

Maybe I will see something we can do to stabilize it.

Never know.

As for your reeds, I would try this...

- turn the reed 90 degrees

- point one end toward the center of the disc

- put the other end right over the magnet

- slide the reed toward/away from the disc center for best results

Of course, I might be wrong, but it's worth a try.

.

Maybe I will see something we can do to stabilize it.

Never know.

As for your reeds, I would try this...

- turn the reed 90 degrees

- point one end toward the center of the disc

- put the other end right over the magnet

- slide the reed toward/away from the disc center for best results

Of course, I might be wrong, but it's worth a try.

.

Well it looks like I'll be doing the Channel Master Perf after all. I outfitted my test stand with a 3" pipe to hold the AJAK and began derusting and cleaning the mount and dish ring.View attachment 88127

Those Perf's are nice! I have the exact same H to H motor as the one in the picture. I had to take it down because it would not take the Canadian winter. I am going to take it apart when I get time and remove and clean the existing grease, and replace it with extreme low temp grease. I could always use a battery blanket or heat tape, but my hydro bill is high enough already.

Reed Switch tech or oddity

Well my education in physics related to magnetism proceeds. Probably easier to go to school, but not cheaper

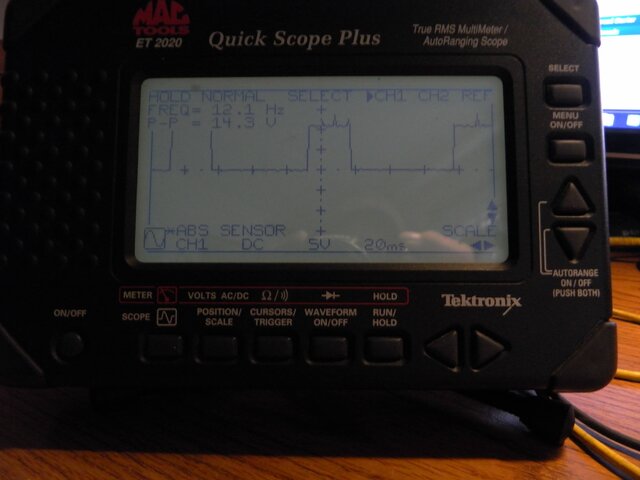

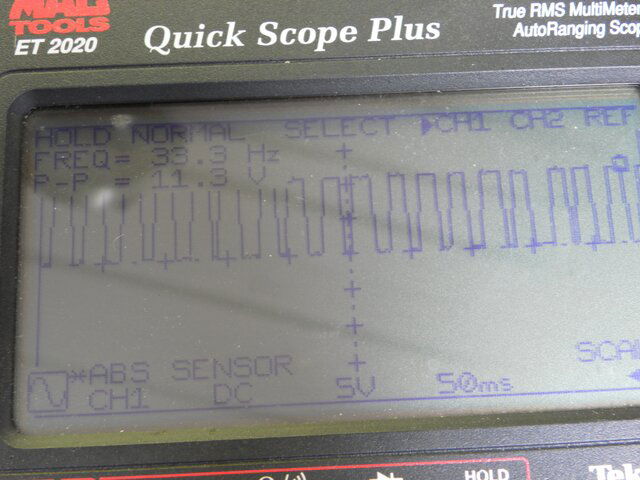

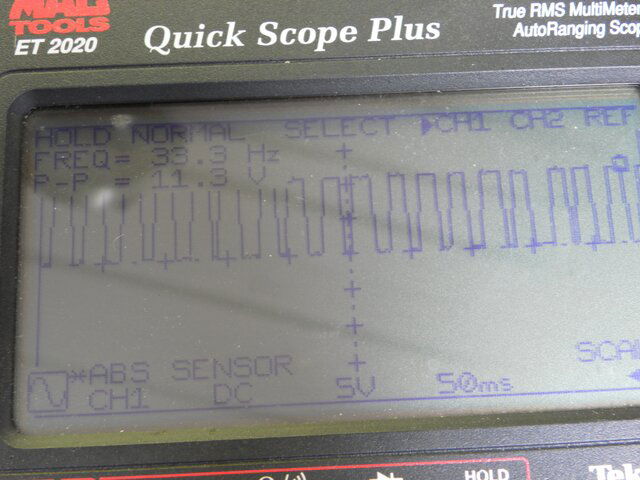

I discovered some interesting characteristics of some reed switches. Like the one that comes with the AJAK. I resurrected my digital lab scope ($60 battery packs) and started playing with a larger switch like in the original AJAK sensor. How does that switch count each magnet twice? Well it's all covered in glue and you can't see this magical beast. The magnets pass by the switch in a linear motion along the switch. Here is the trick as I see it.

As the magnet approaches the switch on one end, the blade in that end of the switch becomes magnetized and attracts the other blade..switch closed.. as the magnet passes over that end and reaches the middle of the switch, both blades become magnetised with the same polarity and the blades push apart..switch open..as the magnet heads for the other end of the switch only one blade is magnetised and ..switch closed a second time..

Makes me wonder if they designed that? Or was it just a side effect?

Well my education in physics related to magnetism proceeds. Probably easier to go to school, but not cheaper

I discovered some interesting characteristics of some reed switches. Like the one that comes with the AJAK. I resurrected my digital lab scope ($60 battery packs) and started playing with a larger switch like in the original AJAK sensor. How does that switch count each magnet twice? Well it's all covered in glue and you can't see this magical beast. The magnets pass by the switch in a linear motion along the switch. Here is the trick as I see it.

As the magnet approaches the switch on one end, the blade in that end of the switch becomes magnetized and attracts the other blade..switch closed.. as the magnet passes over that end and reaches the middle of the switch, both blades become magnetised with the same polarity and the blades push apart..switch open..as the magnet heads for the other end of the switch only one blade is magnetised and ..switch closed a second time..

Makes me wonder if they designed that? Or was it just a side effect?

Last edited:

While waiting for switches I have been paying attention to the rest of the dish. Making sure all the nuts and bolts are there. Checking how it was assembled. I did not like the location of the feed supports. They were mounted at the 3,6,9,and 12 o'clock positions, but not perfectly as that puts them on a rib and no way for the bolt to pass through the outer rim of the dish and put a nut on it. So it looks funny with the supports not lining up with the ribs of the dish. I wanted to move them 90° and locate them on a rib point. So I used 1/4" nutserts. They work very well  http://www.enfasco.com/nutsert.php?kw=nutsert&gclid=CPPun4bZ7bcCFUVyQgodv2cAmQ

http://www.enfasco.com/nutsert.php?kw=nutsert&gclid=CPPun4bZ7bcCFUVyQgodv2cAmQ

No need for an expensive tool to install them. I used a 1/4' star washer, 5/16" nut and 1/4" bolt to install them.

No need for an expensive tool to install them. I used a 1/4' star washer, 5/16" nut and 1/4" bolt to install them.

I got the normally closed switches and seems to be just what I need. I've built the perfect sensor  , problem is, it doesn't work any better or worse than the original. A 10 magnet wheel and a single reed switch. But add a second switch, the count doubles, and the VBox freaks out. Good pattern on the scope, but the VBox cannot count that fast. It starts having trouble at 20hz and the double switch gives it 40hz. (40 counts per second) I guess I'm forced to pull the GBox and see if it's counter can handle it. And if it does, where am I going to come up with one of those for this dish? Dang!

, problem is, it doesn't work any better or worse than the original. A 10 magnet wheel and a single reed switch. But add a second switch, the count doubles, and the VBox freaks out. Good pattern on the scope, but the VBox cannot count that fast. It starts having trouble at 20hz and the double switch gives it 40hz. (40 counts per second) I guess I'm forced to pull the GBox and see if it's counter can handle it. And if it does, where am I going to come up with one of those for this dish? Dang!

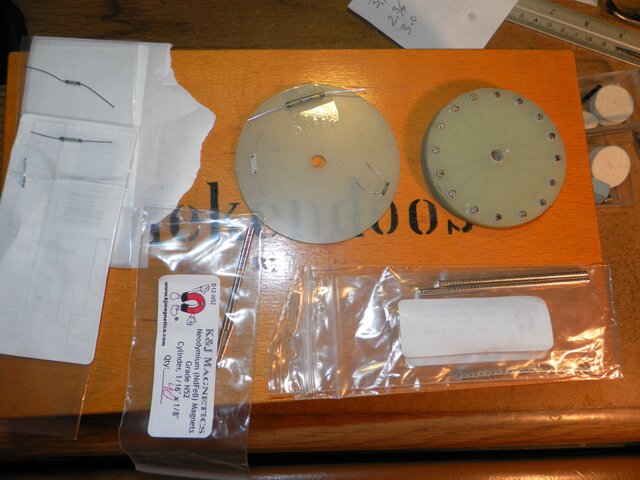

It's being an elusive goal, improving the AJAK sensor, and making it accepted by the controller. In a another attempt to improve the signal, I'm building another two magnet wheels with N35 discs. These are a lower power than the N42 magnets I've used so far. I could also increase the power to N52, but from what I'm seeing, a decrease may give me some more flexability in switch arrangement. So far I've built 6 wheels using 96 magnets. I've bought 17 reed switches to play with. Broken about 5 of them. The little glass ones are very fragile. In concept, you would think you could increase the resolution by 10X easily. But in practice I'll be extremely fortunate to double it. I keep running up against the VBox limitations on this project. I may have to put this on hold until a better controllor is available. But yet I persist. I guess it's something to do for awhile

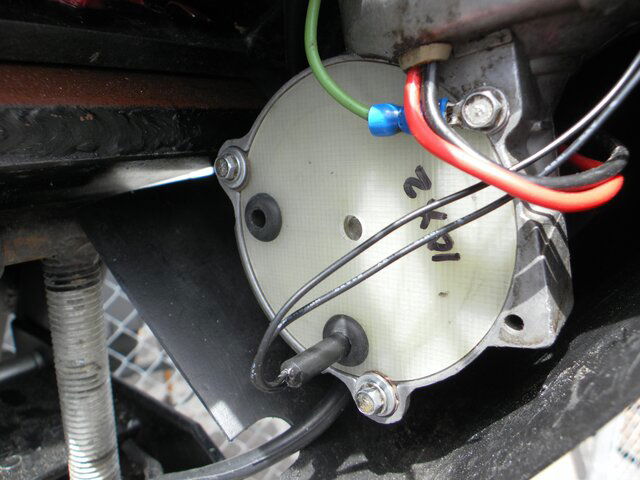

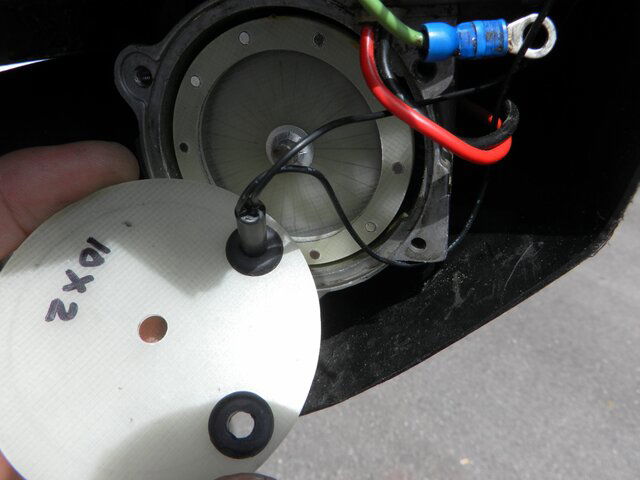

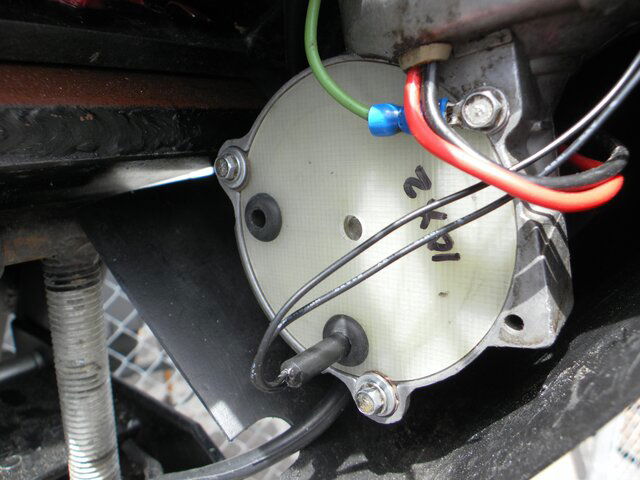

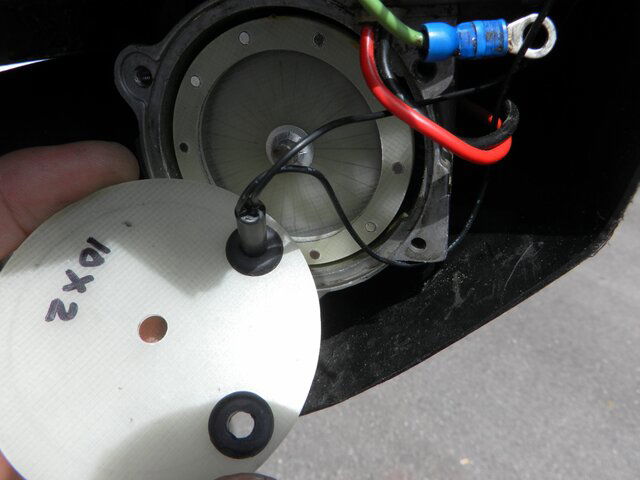

I have finally accomplished the task of doubling the count of the stock AJAK. The lower power Grade N35 magnets did not work at all. But,I have figured out my issues with the VBox X and it will count the sensor reliably up to the 2000 count limit. Which does not cover the range of the AJAK but will cover my LOS. I have .05° resolution with the VBox. And should be .025° with the GBox. The VBox is capable of the .05 degree movement, but not reliably. It will move two counts when asked to move one frequently.

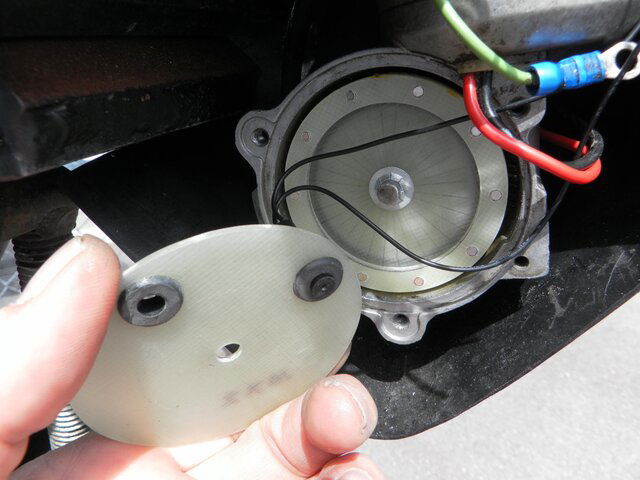

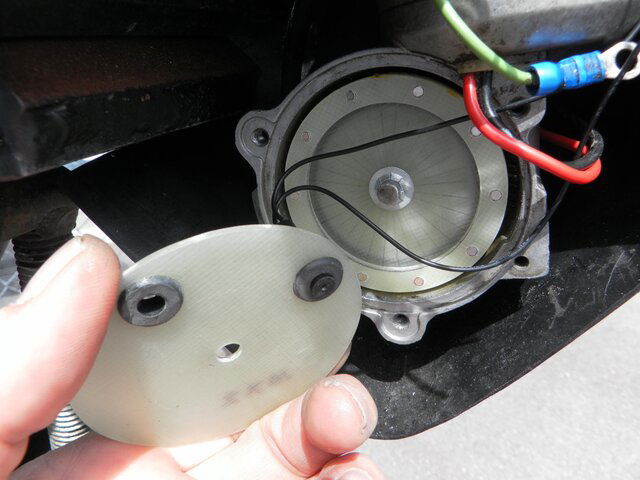

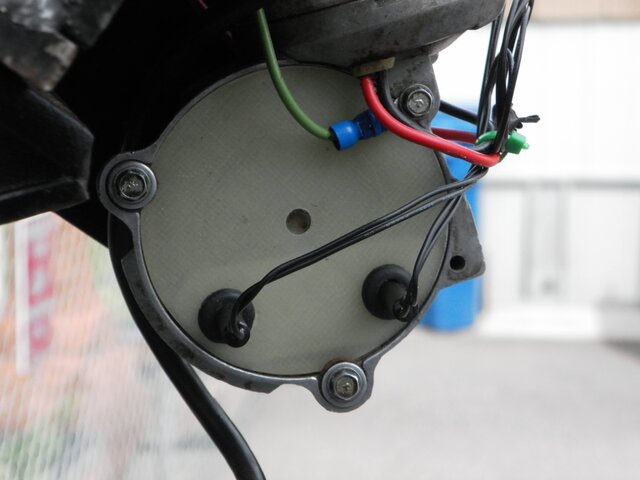

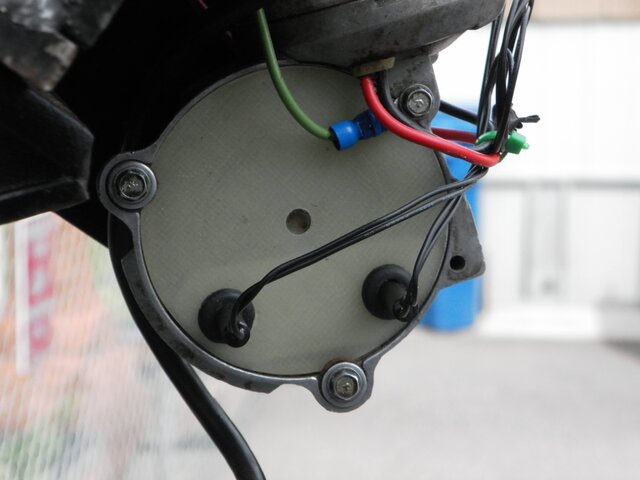

I used a 10 magnet wheel with two SPST NC reed switches to get 20 counts per revolution of the sensor wheel. The magnets axially magnetised and arranged in the wheel with the same polarity up. I found if you alternate polarities with magnets that close together, they cancel each other out and the switches do not operate. I experimented with a ferrous metal plate to try and focus the magnetic fields. It had little effect. Slide one of the switches out of the cover and you have a stock counter.

I used 10 magnets 1/8" X 1/10' Grade N42 (D2H1) from K&J Magnetics $1.40

two reed switches SPST-NC molded body, free hanging inline (59025-040-ND) $4.52 ea from Digi-Key

one 1/4" shaft retainer $.47 from ACE Hardware

Two 1/4" grommets not sourced(on hand)

I sheet of 1/8" thick material non-ferrous (on hand) Lexan may be good?

I used a 10 magnet wheel with two SPST NC reed switches to get 20 counts per revolution of the sensor wheel. The magnets axially magnetised and arranged in the wheel with the same polarity up. I found if you alternate polarities with magnets that close together, they cancel each other out and the switches do not operate. I experimented with a ferrous metal plate to try and focus the magnetic fields. It had little effect. Slide one of the switches out of the cover and you have a stock counter.

I used 10 magnets 1/8" X 1/10' Grade N42 (D2H1) from K&J Magnetics $1.40

two reed switches SPST-NC molded body, free hanging inline (59025-040-ND) $4.52 ea from Digi-Key

one 1/4" shaft retainer $.47 from ACE Hardware

Two 1/4" grommets not sourced(on hand)

I sheet of 1/8" thick material non-ferrous (on hand) Lexan may be good?

I recall you mentioning you weren't getting square waves from your switches.

So, you wired the two NC switches in series?

Pretty clever.

What was the cause of instability you reported before?

So, you wired the two NC switches in series?

Pretty clever.

What was the cause of instability you reported before?

There is some quirkyness to the PowerMax VBox X. I'm not sure if the DMSI VBox 7 does the same stuff. Apparently it won't continuously run with the manual buttons on the unit with a high count rate. Even an unloaded stock AJAK is too fast. But put a heavy dish on it and you would never know. However, if you use the remote E & W buttons this thing will fly and not care about fast or weak counts. I wasn't using a remote because I didn't have a set of batteries handy. But I got the other VBox X from the house and the remote and discovered this stuff. Well it was just what I needed to evaluate and adjust everythingWhat was the cause of instability you reported before?

Some corrections to the above posts: The parts list, the sheet of material is not 1/8" more like 1/16". I also used a tube of Krazy Glue (cyanoacrylate) to assemble the discs and glue in the magnets.

Regarding the feed supports, I wanted to move them 45° not 90° as posted. (90° would be no move at all )

)

And I'm not finished just yet with the sensor mod. I actually have some different switches on the way I still have some ideas not tested yet. And of course I get to install this dish soon I hope

I still have some ideas not tested yet. And of course I get to install this dish soon I hope

Anole, re the switches, Yes, Normally closed, they are wired in a series. If they were "normally open" they would be wired in parrallal

Regarding the feed supports, I wanted to move them 45° not 90° as posted. (90° would be no move at all

And I'm not finished just yet with the sensor mod. I actually have some different switches on the way

Anole, re the switches, Yes, Normally closed, they are wired in a series. If they were "normally open" they would be wired in parrallal

I disassembled the Laser C/Ku this morning. I had to start at 5:30am to beat the heat. It took two hours and I was sweating heavily in the heat when finished. I borrowed my one buddies dish lifter setup but didn't like the idea of using a come-a-long with it. There just isn't enough cable on a normal come-a-long and the rope one he has can slip (needs new rope) So I got a 1000 lb hand winch with 32 feet of cable and made a bracket to attach to the dish lifter

Overcast today  time to install this dish. I tweaked the scalar position with a laser pointer I have. I wrapped it with tape so it just fits inside the Ku tube on the Bullseye II. I turn it inside the tube and watch the spot to calibrate the pointer then adjust the scalar so it looks at exact center

time to install this dish. I tweaked the scalar position with a laser pointer I have. I wrapped it with tape so it just fits inside the Ku tube on the Bullseye II. I turn it inside the tube and watch the spot to calibrate the pointer then adjust the scalar so it looks at exact center

I mounted the lifter on my pole. Moved the assembled dish under the pole and lifted the dish ring and dish off the AJAK. While the dish is hanging, I removed the AJAK from the stand and installed it on the pole. I finished raising the dish and bolted it in place.

Well I lost my overcast, time to quit for now. I'm happy with the way it went so far, nice and easy

I mounted the lifter on my pole. Moved the assembled dish under the pole and lifted the dish ring and dish off the AJAK. While the dish is hanging, I removed the AJAK from the stand and installed it on the pole. I finished raising the dish and bolted it in place.

Well I lost my overcast, time to quit for now. I'm happy with the way it went so far, nice and easy

I got this dish dialed in  I LIKE the way this dish works. A very definate improvement over the previous dish, especially in the KU band. Overall two thumbs up!

I LIKE the way this dish works. A very definate improvement over the previous dish, especially in the KU band. Overall two thumbs up!

- Status

- Please reply by conversation.

Similar threads

- Replies

- 14

- Views

- 851

- Replies

- 5

- Views

- 759

- Replies

- 9

- Views

- 1K

- Replies

- 26

- Views

- 2K

- Replies

- 0

- Views

- 156