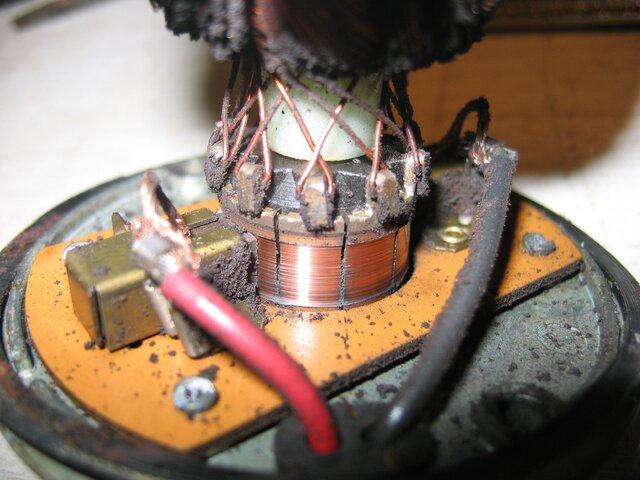

Pull the brushes out by unscrewing the black plastic caps on the wire lead end of the motor, pay attention to the curvature of the brushes so they go back in with the same orientation. You should be able to read the numbers on the bearings, and get replacements if they're pitted or corroded. Other wise, just clean and regrease. With small motors, grease is like a womans make-up, a little is way better than too much. Several on-line bearing houses to choose from. Im surprised it has real bearings instead of bushings, sign of a good quality motor. Take a photo of the commutator, it looks like a bunch of little copper barrs around one end. If it's not gouged or burnt black, it's probably a good armature. I've rebuilt hundreds of small motors, and have some assorted brushes if you need them, 3/8" or longer is ok, less than that replace them.

Are the brushes captive? right now I have the end of the motor that the wires come out of held in place with a u bolt hoseclamped to the motor housing. What do I have to watch for when I pull that cap off? Remember I am TOTALLY ignorant here, I know NOTHING about the guts of a motor. ZERO. I don't know what brushes look like or where they go.

:

:

![IMG_1761[1].JPG](https://cdn.satelliteguys.us/xen/data/attachments/26/26735-649801efee29e049023048944187cd26.jpg?hash=ZJgB7-4p4E)