I do have a 12VDC 35A Astron power supply but I wasn't sure if 12V would be enough. I'll try powering the actuator with 12V and see what happens. This is my older actuator but I was hoping to get another 20 years out of it. I'm not touching the wife's actuator!Try with just a 12volt car battery hooked to the actuator motor, and see if that moves it freely. 12 volts is enough, though it'll move very slowly if good.

new 1.2 meter dish and 12 footer

- Thread starter ZetaMale

- Start date

- Latest activity Latest activity:

- Replies 250

- Views 27K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I've been successful using just 12 volts to test various actuators. Like I said, they work if good, just slowly. As long as the battery can put out at least 5-6 amps, no issues. I even have an old set of UPS batteries I have wired in parallel that I use for test purposes, and it's capable of moving my actuator while connected to my dish.

I hooked up my 12 V power supply to the cabling from the point it connects to the Vbox/Gbox. The antenna does move in both directions so the actuator itself seems to be OK. I'm not sure about the reed sensor though. It looks like it's pulsing but I don't have an analog meter. My digital ohmmeter seems to indicate fluctuations in resistance though. When the actuator stopped, my ohmmeter showed 2 ohms through the reed. I guess I should get a reed on order tomorrow? So, this test proved that the wiring is good. I do have a hall sensor that I was intending to install but I need to do a mod on a Gbox or Vbox to use it. Since I'm moving a Gbox to a different enclosure this might be a good time to do this. By the way, my Gbox is bad. I guess when it rains it pours. I'll get this antenna setup working yet!

I'll contact Venture tomorrow unless you know of a cheaper source. The hall sensor that I bought from them was over $50. I assume that reeds are cheaper.Reed sensors can magnetize permanently, or flash-weld together. I've also seen in some cases they can pit like relay points, which causes high resistance reads from them.

Lifetime supply for $6, with free shipping:. Amazon product ASIN B01NBPDU04I'll contact Venture tomorrow unless you know of a cheaper source. The hall sensor that I bought from them was over $50. I assume that reeds are cheaper.

I take it that these are soldered in to place?Lifetime supply for $6, with free shipping:. Amazon product ASIN B01NBPDU04

It depends on the actuator. Some are soldered, and some are simply crimped to tabs under the screw connector panel. Just be very careful if you attempt to bend the wire connectors at each end. You should hold the side closest to the glass with a needle-nose pliers, and then bend the end as needed with another pliers.I take it that these are soldered in to place?

Good thing they're cheap. Are hall sensors less fragile? It would take more installation time to do those though.It depends on the actuator. Some are soldered, and some are simply crimped to tabs under the screw connector panel. Just be very careful if you attempt to bend the wire connectors at each end. You should hold the side closest to the glass with a needle-nose pliers, and then bend the end as needed with another pliers.

I don't know anything much about Hall sensors, sorry. I've never dealt with any other than simple mechanical hand crank, the old potentiometers types, and reed switch types.

I worked in electronics for 40 years but never worked with reed switches or hall sensors. I haven't changed any out on actuators either. I suppose it's a better idea to change out the actuator when something goes bad even though it's just a reed switch. Who knows what will fail next? But I have no desire to spend the time and effort to restore an actuator. I think a 36" actuator would work good on this new antenna though. But I'm going to take the cheap route this time. The principles behind them are simple enough. But I do know they're not a straight swap. I want to modify both of my antenna setups for hall effect counters but I'm going to do just one for now - if I can figure out how to do it. Anyway, I just placed an order for those reed switches but Christmas seems to have slowed down delivery times - even for Amazon Prime. CV-19 probably isn't helping either. So I have to wait until Wednesday for them to arrive. I couldn't get the switches locally. In the meantime, I've parked the TEK dish on a sat that I normally visit.

Mine was soldered. Sure was a LOT of epoxy inside of this thing. I had to use a heat gun on it's lowest setting to get the cover off. I'm wondering if all that epoxy is necessary.It depends on the actuator. Some are soldered, and some are simply crimped to tabs under the screw connector panel. Just be very careful if you attempt to bend the wire connectors at each end. You should hold the side closest to the glass with a needle-nose pliers, and then bend the end as needed with another pliers.

Well, as another way to do it for shock & weather protection, would be to encased it in clear silicone bathtub caulking. That'll do nearly the same to encapsulate it, yet could be peeled off in the future. Just let it cure for a good 24 hours before remounting it on the motor.Mine was soldered. Sure was a LOT of epoxy inside of this thing. I had to use a heat gun on it's lowest setting to get the cover off. I'm wondering if all that epoxy is necessary.

Exactly. Then watch your DMM on low ohms and look for infinite/close to zero ohms across the reed switch terminals as the magnet spins. As always, not to confuse anyone. It's a good time also to remove the sensor leads at the positioner and short them , check resistance on the leads at the actuator.Try with just a 12volt car battery hooked to the actuator motor, and see if that moves it freely. 12 volts is enough, though it'll move very slowly if good.

Or while the dish is slowly moving run back in and check the sensor leads for reed switch open/closes (disconnected from the positioner of course).

Replacing the reed fixed the problem. I plan to replace it with a hall sensor whenever the relay shows up and keep this reed sensor as a backup.

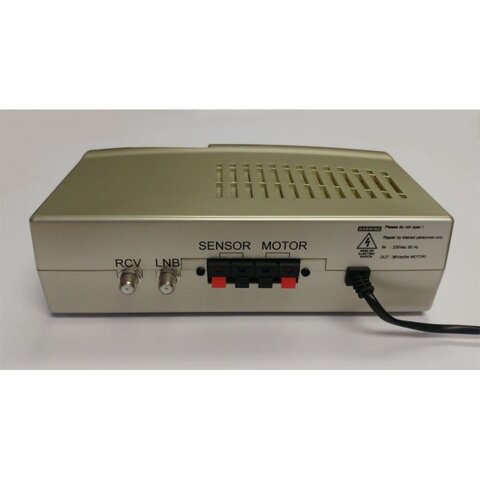

arlo Here is the info that you asked for. I was going to try to put them in my Amazon Drive but that feature seems to have disappeared. Anyway, one is an image of the back of my latest mover (PR1200) and the other is the manual for my Gbox. I can't seem to find a manual for the PR1200 (maybe there wasn't one?). I have a good idea of how to connect the relay between the box and actuator, though. I can see how it'll work for both a reed and hall effect device.

Attachments

If you search on PRIMESAT V-BOX PR1200, every link seems to say a user manual comes with it.

If you didn't get one, I suggest emailing and asking Rick if his are supposed to come with one.

RickCaylor@aol.com

If you didn't get one, I suggest emailing and asking Rick if his are supposed to come with one.

RickCaylor@aol.com

I was going to suggest WeTransfer. Thanks so much. The results will show soon.arlo Here is the info that you asked for. I was going to try to put them in my Amazon Drive but that feature seems to have disappeared. Anyway, one is an image of the back of my latest mover (PR1200) and the other is the manual for my Gbox. I can't seem to find a manual for the PR1200 (maybe there wasn't one?). I have a good idea of how to connect the relay between the box and actuator, though. I can see how it'll work for both a reed and hall effect device.

I found the manual that came with it. I scanned it into my computer and uploaded the merged pdf's to satguys.If you search on PRIMESAT V-BOX PR1200, every link seems to say a user manual comes with it.

If you didn't get one, I suggest emailing and asking Rick if his are supposed to come with one.

RickCaylor@aol.com

Similar threads

- Replies

- 4

- Views

- 536

- Replies

- 4

- Views

- 1K

- Replies

- 18

- Views

- 851

- Replies

- 4

- Views

- 384