new 1.2 meter dish and 12 footer

- Thread starter ZetaMale

- Start date

- Latest activity Latest activity:

- Replies 250

- Views 27K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

They don't give you much time to edit a previous post. Anyway, I just hooked up a relay to my Vbox with a standard reed sensor. I'll see how well it works over the next few days for a test before trying a hall sensor. Heh, I still haven't aligned the new dish but now I need to wait for warmer weather.

Heh, I got the 1.2 meter mounted to the Powermax SG9120 but when I went to attach the cable to the receiver port, the F connector fell out. It's repairable but I need a thin wall 7/16 nut driver to get it back into place. But it turns out that I need to remove the board inside of the motor because there's a nut on the inside that needs to be reattached. Looks like the only way to do that is to disconnect the LBNF F connector to remove the board. By the time I get this fixed it'll be dark and it'll be stormy and windy tomorrow. I sure do have a lot of bad luck. I still need to find the Ku LNBF holder that fits this antenna and LNBF. As far as the C band antenna, it needs additional fine tuning but I am getting decent performance from 87W to 127W. If I get time and I'm so motivated, I'll adjust feed, elevation, and declination today.

Make one,grind down an old 7/16 socket till it fits.Since I can't find the right tool locally or online to repair my SG9120, I'll have to buy a new HH motor for my 1.2 meter.

I have both a normal and deep well 7/16 socket but they need to be a thinner wall. I don't have a grinder so eiether way it'll cost some bucks for either a grinder or new motor. The motor might not be in stock though.Make one,grind down an old 7/16 socket till it fits.

Do you have a file or sandpaper available? A grinder is just a high speed substitute for these. A dremel tool would work. Plenty of options to remove metal. Sliding the socket or nut driver on concrete would even work. I would chuck an extension and the socket onto my electric drill and get at it. Most of us can think outside the box here, but few of us know that we make our own boxes.

Sent from my Commodore P.E.T. using the SatelliteGuys app!

I have both a normal and deep well 7/16 socket but they need to be a thinner wall. I don't have a grinder so eiether way it'll cost some bucks for either a grinder or new motor. The motor might not be in stock though.

Sent from my Commodore P.E.T. using the SatelliteGuys app!

Got a Harbor Freight nearby,for 10 or 15 bucks you can get a 4 1/2 inch angle grinder.With all the fab work you've been doing lately,really handy to have around,and a lot cheaper than a new motor.I have both a normal and deep well 7/16 socket but they need to be a thinner wall. I don't have a grinder so eiether way it'll cost some bucks for either a grinder or new motor. The motor might not be in stock though.

If there is enough space: Place a small slotted screwdriver on the hex side of the nut. Tap the screwdriver with a small hammer forcing the nut to turn counter clockwise. Once nut is loosened, you can probably finish removing the nut using only the screwdriver. A bit tedious, no doubt.

But be careful banging around so you don't break something.

But be careful banging around so you don't break something.

I succeeded once with one of those:

Did you try that too?

(I didn't read the whole thread back)

Re: your ancient quote from Madison: That is really of the old days.

The modern way of course is: Flood the zone with sh*t, and demonize the fact-checkers.

Greetz,

A33

Did you try that too?

(I didn't read the whole thread back)

Re: your ancient quote from Madison: That is really of the old days.

The modern way of course is: Flood the zone with sh*t, and demonize the fact-checkers.

Greetz,

A33

Not enough clearance for that either. I'm going to put my 90cm back up until I can get this fixed. Or I might wait for an Stab HH120 to become available again instead of trying to fix this thing. I don't know if the XCruiser XH240 H-H Motor at TEK2000 is a decent motor but the price isn't too bad.I succeeded once with one of those:

View attachment 149555

Did you try that too?

(I didn't read the whole thread back)

Re: your ancient quote from Madison: That is really of the old days.

The modern way of course is: Flood the zone with sh*t, and demonize the fact-checkers.

Greetz,

A33

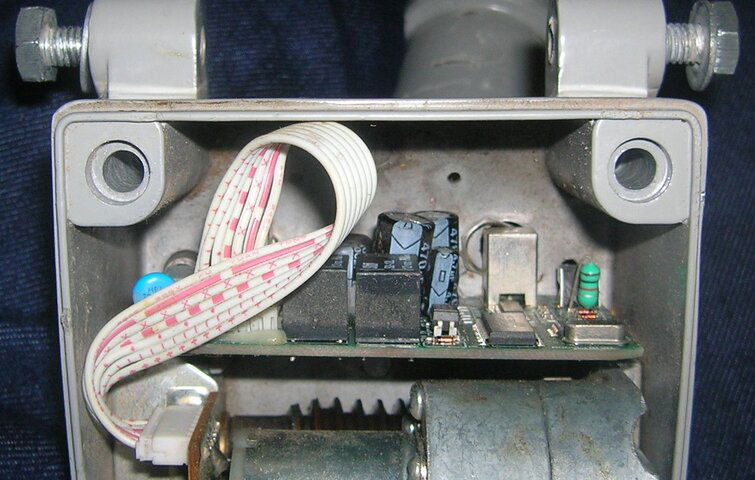

Is it possible to desolder and get the board out of the way and try loosening it from the back?I got a F connector removal tool today but it won't fit down inside of the well where the nut is recessed by 1/4 inch. There's probably a tool to get down in there but I'm going to try removing the nut the hard way.

Just throwing it out there as I have no idea what the other side looks like.

I'll have to look closer to see if that can be done but upon a brief look it doesn't appear so. Too bad I don't have a maintenance manual that would give me instructions so that I don't mess it up.Is it possible to desolder and get the board out of the way and try loosening it from the back?

Just throwing it out there as I have no idea what the other side looks like.

Actually, it is not nut from outside....it is all body of the connector should be unscrewed. So, as waylew has said, you better desolder the wire from inside and then unscrew whole connector. Put some WD40, that might help.I'm going to try removing the nut the hard way.

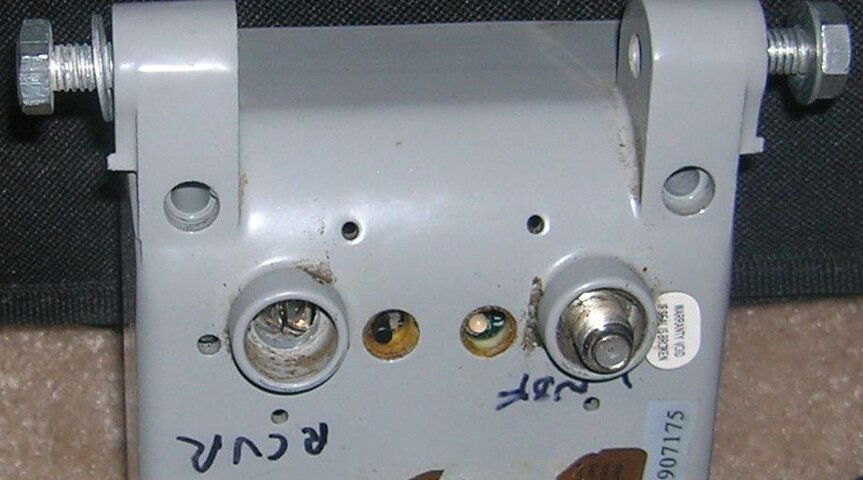

That how the connector look like , no nut there.

Attachments

Last edited:

I was thinking it might be one of those,but it doesn't look like there are any threads in the other hole with the missing connector.Actually, it is not nut from outside....it is all body of the connector should be unscrewed. So, as waylew has said, you better desolder the wire from inside and then unscrew whole connector. Put some WD40, that might help.

That how the connector look like , no nut there.

There's a nut on both the inside and outside that holds a barrel F connector in place. I can see a nut on the inside. As for desoldering, there's nothing to desolder because the F connector is a barrel connector. See attached image of the F connector that fell out from the right side. Two of the attached images show the loose inside nut for the right connector. Near as I can tell, that board won't slide out until the outside nut on the left connector is removed.Actually, it is not nut from outside....it is all body of the connector should be unscrewed. So, as waylew has said, you better desolder the wire from inside and then unscrew whole connector. Put some WD40, that might help.

That how the connector look like , no nut there.

Attachments

Can not unscrew it.... drill it out.Near as I can tell, that board won't slide out until the outside nut on the left connector is removed.

Not enough clearance for that either.

Well, I've got about 5 of those thin/small pliers, and just one of them was thin enough and could reach enough inside to dismantle the nut, in my case.

What might help, if you could reach the inside nut a bit to loosen that? It would make the outside nut more manoeuvrable, I guess.

Greetz,

A33

Similar threads

- Replies

- 4

- Views

- 528

- Replies

- 4

- Views

- 1K

- Replies

- 18

- Views

- 841

- Replies

- 4

- Views

- 377

Users Who Are Viewing This Thread (Total: 0, Members: 0, Guests: 0)

Who Read This Thread (Total Members: 10)

Latest posts

-

-

-

-

What satellites are good to pick up with this?

- Latest: HoppertheKangaroo18

-