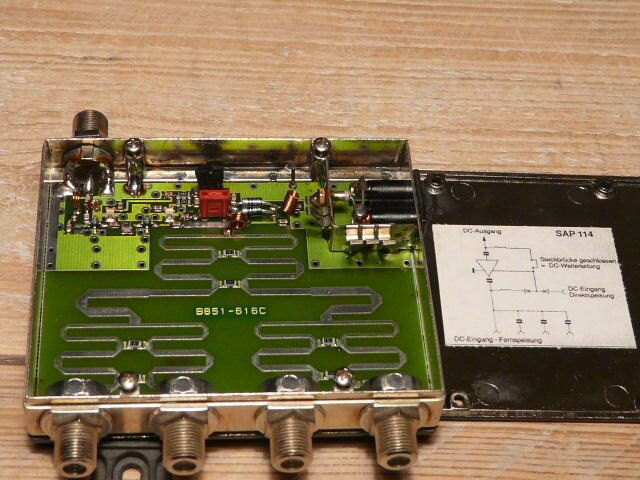

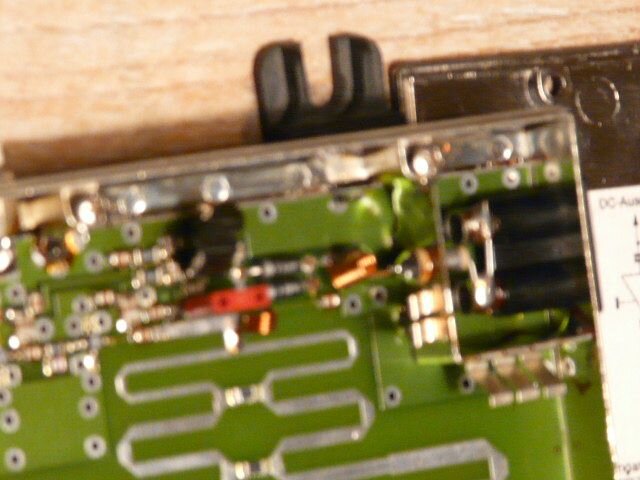

Still trying to externally power the HH-120 motor without breaking into the motor, I decided to try to copy qwert1515's device shown here

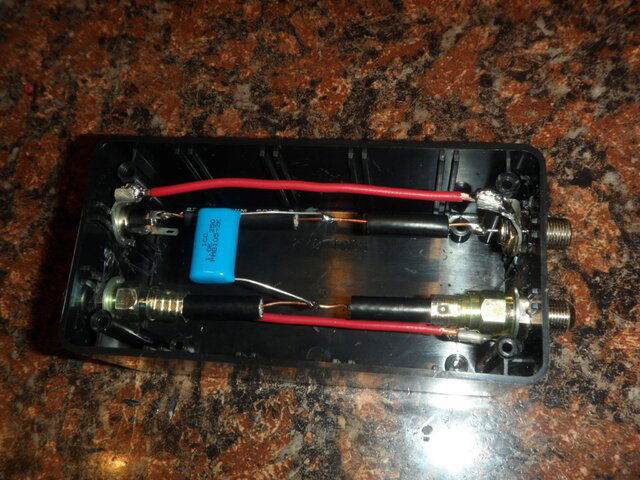

There is actually still a Radio Shack in operation the next town over. I made the 30 mile trip and bought a few items. Here is what I came up with:

The main difference between qwert1515's device and mine is the capacitor. I was limited to what Radio Shack had on hand and the 1.0 uF K 250v is as close to the 155J 400v in the previously mentioned thread.

I'm not an electronics expert, but I think the capacitors would be similar enough in value to work?

The motor power input is for a laptop power source (19v). Pass through on the receiver to LNBF port worked fine. However, still couldn't get the motor to move with this external power source.

There is actually still a Radio Shack in operation the next town over. I made the 30 mile trip and bought a few items. Here is what I came up with:

The main difference between qwert1515's device and mine is the capacitor. I was limited to what Radio Shack had on hand and the 1.0 uF K 250v is as close to the 155J 400v in the previously mentioned thread.

I'm not an electronics expert, but I think the capacitors would be similar enough in value to work?

The motor power input is for a laptop power source (19v). Pass through on the receiver to LNBF port worked fine. However, still couldn't get the motor to move with this external power source.