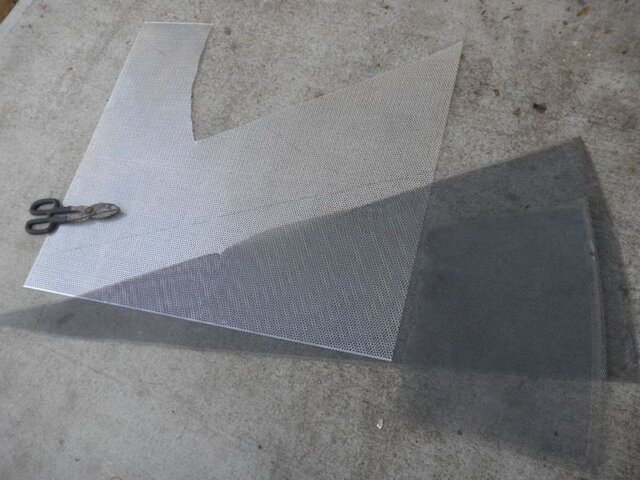

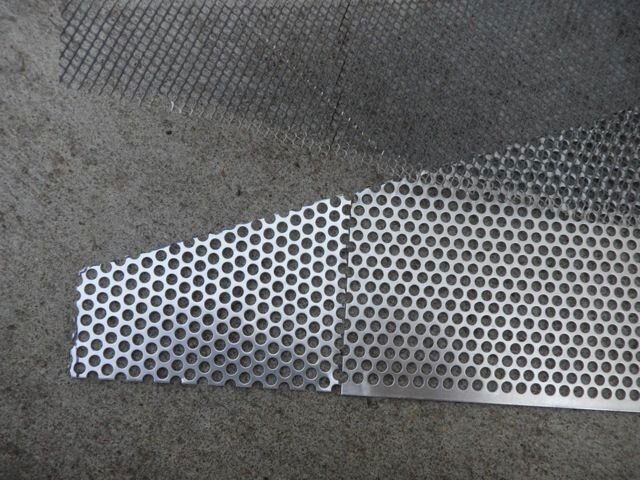

So I only thought the large portions of repair were done. When I looked at the new perforated and straightened mesh compared to the remainder of the dish, I couldn't leave it alone.

I wound up removing all the panels for straightening and to try to remove hail dents. Used a piece of pipe to roll out the mesh and a rubber mallet to further flatten the hail dings.

Replaced the mesh with the original topside down, then massaged out the dings further. After that, some time was spent with a small propane torch to help tighten up areas and do a little more straightening. A bit more massaging and I called it good.

Once I was more satisfied with the straightening job, added a couple of coats of primer and paint to the segment face. Trying to closely match the original Winegard gray color, Krylon 'Rust Tough Enamel' Primer RTA-9205 is a very close flat and then for topcoat, Duplicolor Machinery Gray (DA-1612).

Here's a photo of the segment that had the majority of repairs performed (before paint):

Photos below resized to under 200 kb

And another panel (after paint):

Looking down a 'typical' panel (after paint):

It's not perfect, but better than when I started.

As the panels are about done, I assessed the hardware from the dish. Most of the hardware was usable but rusty. Stainless hardware is not readily available, without driving 30+ miles one way plus time involved. I wanted to try something different than sandblasting or wire wheel. With as much rust removal as I've done over the years, I have never tried electrolysis and decided that it would be a neat thing (esp. for the kiddos to see).

Put together a bucket and began the rust removal from the fasteners:

After brewing for a while, an example of the cleanup (it's not quite there yet):

Cleaned off residue and wound up letting the parts soak in the electrolysis bucket longer until it was all black. Once the process was complete, primed and painted the hardware.

All in all, after years of trying other methods for rust removal (e.g., naval jelly, sandblasting, wire wheel, etc.), I'm pretty happy with the electrolysis method.

!

!

I assume that was from a bad repair job rather than OEM. I didn't find new bushings,but I replaced the bolts with a slightly larger metric bolt that was NOT threaded in the bushing area. Tightened it up nicely...had to drive them on with a few taps.

I assume that was from a bad repair job rather than OEM. I didn't find new bushings,but I replaced the bolts with a slightly larger metric bolt that was NOT threaded in the bushing area. Tightened it up nicely...had to drive them on with a few taps. lol

lol