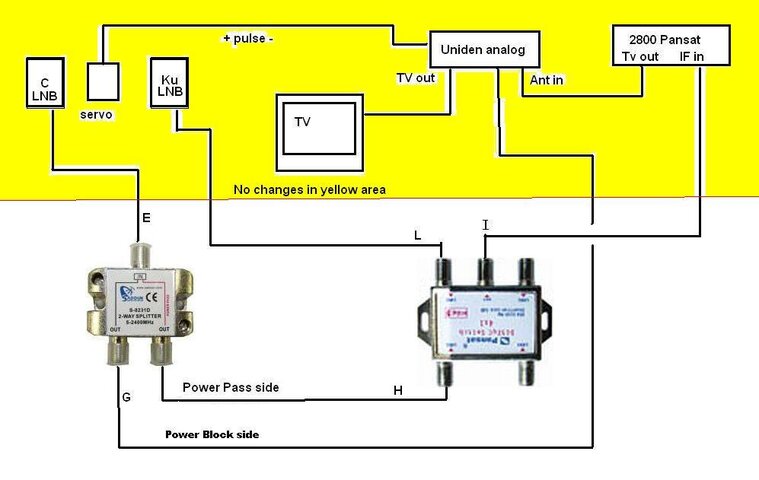

Are the, what you have labeled as splitters, just splitters, and not disqc or 22khz switches? Any ID numbers on them?

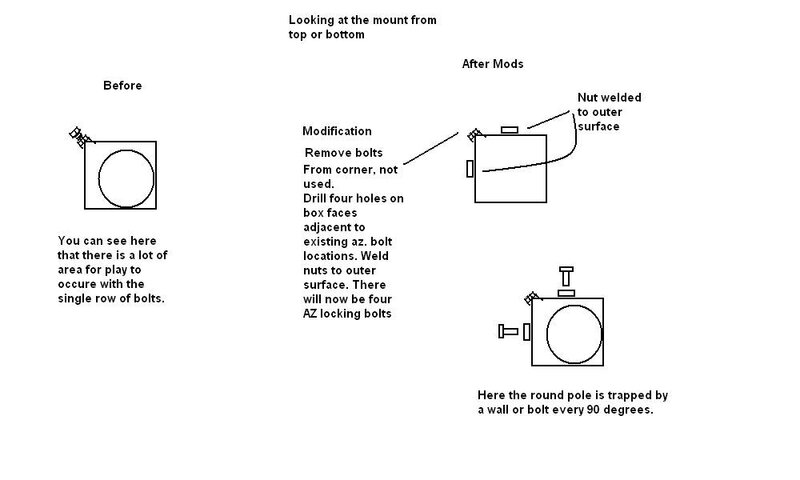

On the square az mount, are there only 2 bolts at the corner of the "box"?

If so, I/ve seen that before, and yes, troublesome, But then, I have to draw something for your mount. Quick and EZ fix I've done on a couple. Just requires a trip to the welding shop.

On the square az mount, are there only 2 bolts at the corner of the "box"?

If so, I/ve seen that before, and yes, troublesome, But then, I have to draw something for your mount. Quick and EZ fix I've done on a couple. Just requires a trip to the welding shop.