Wanted motor for 24" Venture ball-screw actuator

- Thread starter primestar31

- Start date

- Latest activity Latest activity:

- Replies 39

- Views 4K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

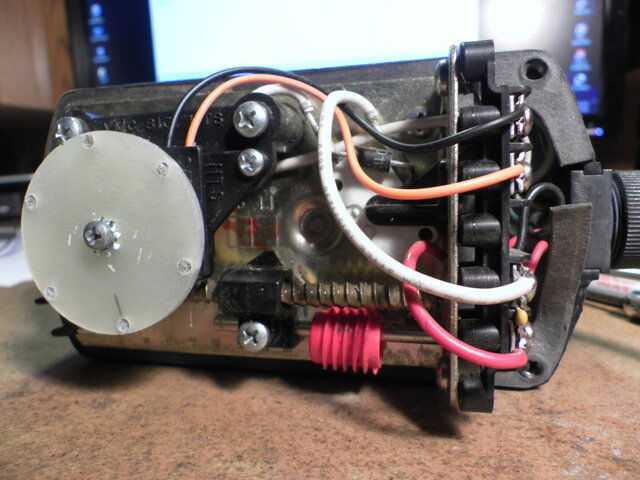

Curious. What are the leading numbers on the belt?I have one of those belt driven Ventures. I only use it for bench testing VBoxes and such. The belt is severely degraded/cracked and not available anywhere. I disconnected the limit system so it can run forever in both directions. Modded the sensor from 32 to 96 counts per inch.View attachment 154216 View attachment 154217 View attachment 154218

I had machinery with off sized timing belts. Available through the mfgr. only. Also had tons of ones a little bit longer from equipment long gone with the same tooth pitch.

Stacked up a couple of roller bearings on a machine screw with spacers. Marked and blew a hole in the frame.

Wa-La! An idler to take up the slack. My "right-hand-girl" told me I should start a YouTube named Riggin'.

Mine only has two double-end gears, and the belt. My belt is still soft, and a bit stretchy as normal. No tears, no damaged "teeth" no obvious stretch or stress marks. I tore down the gear box, cleaned the spindles with a little carborundum paper, rootered the gear holes, scraped out the crud on everything, and reassembled it after lubing the spindles and where the gears mesh with Red N Tacky grease. It all appears to be working perfectly again, as tested with my old V-box X. I still have to bolt it back to the actuator tube and to adjust both the limit switches, and seal the gear box with some clear silicone caulk.No other numbers on the belt, just what you see.

There are a lot of gears along with that belt in the gearbox. The way I remember it there wouldn't be any place for an idler in there.

View attachment 154219

Last edited:

Hmmm. 34 teeth? How about pitch between teeth in./mm. How wide? And maybe a macro of the tooth style?Curious. What are the leading numbers on the belt?

I had machinery with off sized timing belts. Available through the mfgr. only. Also had tons of ones a little bit longer from equipment long gone with the same tooth pitch.

Stacked up a couple of roller bearings on a machine screw with spacers. Marked and blew a hole in the frame.

Wa-La! An idler to take up the slack. My "right-hand-girl" told me I should start a YouTube named Riggin'.

Wanna bet? A quarter?

arloCurious. What are the leading numbers on the belt?

I had machinery with off sized timing belts. Available through the mfgr. only. Also had tons of ones a little bit longer from equipment long gone with the same tooth pitch.

Stacked up a couple of roller bearings on a machine screw with spacers. Marked and blew a hole in the frame.

Wa-La! An idler to take up the slack. My "right-hand-girl" told me I should start a YouTube named Riggin'.

Here's some photos of my belt.

Dimensions:

5/16" wide x 7-1/8" around the outside (circumference) using a cloth tape measure to get as exact as I can.

34 'teeth' I counted them multiple times to make sure. EACH 'tooth' is 3/32" wide. There is 1/8" 'space' between individual teeth.

Labeled "Goodyear' and "68XL" seems to be the part number on mine.

The really large last photo of the belt, is a 3x macro taken on normal lined school paper.

Take your pick then.

Edit:

I know my supplier, Florida Belting had tubes of toothed "to be" belting in stock and would custom slit it to your specs.

vbeltoutlet.com

vbeltoutlet.com

Edit:

I know my supplier, Florida Belting had tubes of toothed "to be" belting in stock and would custom slit it to your specs.

68XL Timing Belt Replacement: 68XL025 68XL037 68XL050 68XL075

68XL Timing Belt Replacement or 68 XL Sychronous belt, Pitch 0.2″/5.08mm , P/N: 68XL025 68XL037 68XL050 68XL075 68XL100 68XL150 68XL200 68XL043 toothed belt , Neoprene Rubber Trapezoid belt. Width 0.25" 0.31" 0.43" 0.5" 0.63" 0.75″ 1″ 1.5″ 2″ any width.

vbeltoutlet.com

vbeltoutlet.com

Oof, $33.00 for shipping. Good find though, proves they are out there anyway,Take your pick then.

Edit:

I know my supplier, Florida Belting had tubes of toothed "to be" belting in stock and would custom slit it to your specs.

68XL Timing Belt Replacement: 68XL025 68XL037 68XL050 68XL075

68XL Timing Belt Replacement or 68 XL Sychronous belt, Pitch 0.2″/5.08mm , P/N: 68XL025 68XL037 68XL050 68XL075 68XL100 68XL150 68XL200 68XL043 toothed belt , Neoprene Rubber Trapezoid belt. Width 0.25" 0.31" 0.43" 0.5" 0.63" 0.75″ 1″ 1.5″ 2″ any width.vbeltoutlet.com

That's a better choice I couldn't find earlier. Thanks!

They'll ship USPS. I ordered a couple, though I went with the 68xl031 model, as it's a better fit with my measured dimensions.

If it fits, I'll let you all know.

Magic Static

Not always. I've been trying to find another place since last night that would ship USPS, and nothing showed up with the right belts."Google is your friend"

They're on ebay too,that's how I found them.Needed a bunch of belts for different lawn mower projects and didn't want to pay NAPA prices.25/30 bucks at napa,7or8 from these guys and they last.After 3 years had to replace the mower drive belt on my ancient Jacobsen,lucky if I got a season from the napa belts.

Huh, Ebay is one site where I looked also, but nobody had that exact belt listed, except one Chinese one that had the price and shipping way up. I should have thought to look at some of the lister companies actual web sites...They're on ebay too,that's how I found them.Needed a bunch of belts for different lawn mower projects and didn't want to pay NAPA prices.25/30 bucks at napa,7or8 from these guys and they last.After 3 years had to replace the mower drive belt on my ancient Jacobsen,lucky if I got a season from the napa belts.

Anyway, thanks, I appreciate it!

That's the trouble with ebay sometimes,you know what you want,you know it's probably there but trying to find it can drive you up a wall.

Ok, I have the motor drive all reassembled, and remounted to the drive arm. Everything is working PERFECTLY. I found a Venture 8 magnet disc to replace the 4 magnet one, and I have an 8-pitch worm gear, so I now have 64 counts per inch instead of the normal 32 counts per inch! That should work perfectly for me, and is plenty of resolution for my needs once the new 10ft dish is up and running.

magic, I received and can CONFIRM that this belt at my link is the exact replacement for the belts in our Venture belt-drive actuator unit. Shipping is only $3.99 USPS. Ignore the photo, because it shows one that looks much wider for some reason:No other numbers on the belt, just what you see.

There are a lot of gears along with that belt in the gearbox. The way I remember it there wouldn't be any place for an idler in there.

View attachment 154219

This one: D&D PowerDrive 68XL031 Timing Belt - Off Road Belts LLC

So, IF you ever want to completely fix and use that actuator with the bad belt, now is your chance. If not, I post it here for future use. Thanks waylew for finding them.

Man, am I a dummy. I forgot to also thank ARLO for his help in the above post, as he's the one that really pushed to get info on the belt, and came up with the initial place to get one. No fault on him that their shipping cost is crazy in a small order like this! It's too late to update the post above, so I'm going to do it in this one!

Thanks again arlo ! Without all your help in all your posts in this thread, the repair wouldn't have gone as well or as fast as it did. It's really appreciated!

Thanks again arlo ! Without all your help in all your posts in this thread, the repair wouldn't have gone as well or as fast as it did. It's really appreciated!

Not a problem! Don't mention it. It's just years in the industry with machinery (postal) using you-know-what loads of belting needing periodic PM replacements made me a little....resourceful?

I knew that XL series belts have a specific profile and that tooth count (not diameter) plus width is the determining factors.

Anyway awesome that you got hooked up. I found these belts through Goodyear and Gates. But it would require a phone call to them and then finding a distributor that may just have them. That was how I rolled some years back as sometimes the machinery manufacturer would backorder...."stuff". Here I say stuff but you know what I'm really thinking.

30 buck bearings. Local source a tube of 10 for 12 bucks.

Habasit belts at 12 bucks a pop. Buy a 500 foot roll that was slit to width for me, get he proper thermal fusing tooling. Recruit a few guys. Go to town.

Sintered bronze bushings. I think the guys are still using my mini lathe to make one-ups. I trained 'em good.

Want to know how I just found out to program my ASC-1 without tethering it to my laptop from across the room?

Slicker than (see above). Haha.

I knew that XL series belts have a specific profile and that tooth count (not diameter) plus width is the determining factors.

Anyway awesome that you got hooked up. I found these belts through Goodyear and Gates. But it would require a phone call to them and then finding a distributor that may just have them. That was how I rolled some years back as sometimes the machinery manufacturer would backorder...."stuff". Here I say stuff but you know what I'm really thinking.

30 buck bearings. Local source a tube of 10 for 12 bucks.

Habasit belts at 12 bucks a pop. Buy a 500 foot roll that was slit to width for me, get he proper thermal fusing tooling. Recruit a few guys. Go to town.

Sintered bronze bushings. I think the guys are still using my mini lathe to make one-ups. I trained 'em good.

Want to know how I just found out to program my ASC-1 without tethering it to my laptop from across the room?

Slicker than (see above). Haha.

I ordered and received a belt from Primestar31's link. It's a perfect fit and looks to be excellent quality too. Where can you buy something for $0.59 now-a-days?

Similar threads

- Replies

- 0

- Views

- 347

- Replies

- 3

- Views

- 376

- Replies

- 17

- Views

- 915

- Replies

- 0

- Views

- 197

- Replies

- 0

- Views

- 399