Von Weise V76-5 Refurbishing Project

- Thread starter TvMind

- Start date

- Latest activity Latest activity:

- Replies 28

- Views 8K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Perhaps Lone Gunman can chime in here as well, seeing he is well-equipped machinist and obviously has some experience doing this acme nut surgery.

Incidentally the weld with the nylon nut would probably damage it, unless I bought one of the brass nuts.

LG are you selling these to members here? Saw a little production line in those photos of yours <nudge nudge wink wink>

<nudge nudge wink wink>

Thanks Arlo, waiting anxiously for your take.

p.s. I may just swallow my pride - which took a beating with last weekends fiasco - and head back to him and just have him do it again, or at least lemd me the tools to do it myself, and this time squeeze those tabs tight.

Incidentally the weld with the nylon nut would probably damage it, unless I bought one of the brass nuts.

LG are you selling these to members here? Saw a little production line in those photos of yours

Thanks Arlo, waiting anxiously for your take.

p.s. I may just swallow my pride - which took a beating with last weekends fiasco - and head back to him and just have him do it again, or at least lemd me the tools to do it myself, and this time squeeze those tabs tight.

Let me see how the nut aligns in the tube to be captured by the tabs.

Looks like you cut one to get the nut out, right? All of my actuators are Saginaw and Houston Trackers because that's what was sold here back in the day and so far just pumping grease into them and wiping out the old gook that squishes out has worked well.

Can you weld the tabs back and then squeeze them back to capture the nut after it's all cooled down?

Is it possible to lay out and drill, tap the tube tabs or perimeter for something like 4 set screws?

Perhaps drill the nut body so the screws go into it far enough to capture but not interfere with the acme screw?

Tap carefully for a real good interference fit and so they go in flush with the tube?

Finish it off with red Locktite so everything stays put?

Hah. I'm cussing you TV, I was out in my shop before my first cup this morning and got greasy as hell running my tubes out to see if they looked like yours.

I'm compelled to add it looks like you used copper anti seize for lube. I'm not sure how it's going to gook-up in time and is why I'm sure a good black molybdenum or synthetic grease wouldn't be better. Plus if you drill your outer tube for a zerk in the right place you could pump more in periodically.

Looks like you cut one to get the nut out, right? All of my actuators are Saginaw and Houston Trackers because that's what was sold here back in the day and so far just pumping grease into them and wiping out the old gook that squishes out has worked well.

Can you weld the tabs back and then squeeze them back to capture the nut after it's all cooled down?

Is it possible to lay out and drill, tap the tube tabs or perimeter for something like 4 set screws?

Perhaps drill the nut body so the screws go into it far enough to capture but not interfere with the acme screw?

Tap carefully for a real good interference fit and so they go in flush with the tube?

Finish it off with red Locktite so everything stays put?

Hah. I'm cussing you TV, I was out in my shop before my first cup this morning and got greasy as hell running my tubes out to see if they looked like yours.

I'm compelled to add it looks like you used copper anti seize for lube. I'm not sure how it's going to gook-up in time and is why I'm sure a good black molybdenum or synthetic grease wouldn't be better. Plus if you drill your outer tube for a zerk in the right place you could pump more in periodically.

Let me see how the nut aligns in the tube to be captured by the tabs.

Looks like you cut one to get the nut out, right? All of my actuators are Saginaw and Houston Trackers because that's what was sold here back in the day and so far just pumping grease into them and wiping out the old gook that squishes out has worked well.

Can you weld the tabs back and then squeeze them back to capture the nut after it's all cooled down?

Is it possible to lay out and drill, tap the tube tabs or perimeter for something like 4 set screws?

Perhaps drill the nut body so the screws go into it far enough to capture but not interfere with the acme screw?

Tap carefully for a real good interference fit and so they go in flush with the tube?

Finish it off with red Locktite so everything stays put?

Hah. I'm cussing you TV, I was out in my shop before my first cup this morning and got greasy as hell running my tubes out to see if they looked like yours.

I'm compelled to add it looks like you used copper anti seize for lube. I'm not sure how it's going to gook-up in time and is why I'm sure a good black molybdenum or synthetic grease wouldn't be better. Plus if you drill your outer tube for a zerk in the right place you could pump more in periodically.

I had the same idea of heating the tabs. I did not remove the old worn nut myself, the retired guy did it for me. He also put the new one in. I am not sure there was a notch for alingment inside the tube, the only notch is at the end of the tube in the photos, but even if there was he probably obliterated it expanding the tabs with his tapered mandrel ( all speculation) . If it weren't for covid I would do the work with him and properly :/

You are right about the "grease" . I could have saved you from the grease detective work and frayed nerves by posting a pic of the tube. But thanks for the trouble, appreciate it.

Yes I am not sure this was a good idea, it felt real good and quiet though but doubt it will hold up. I may have a tube of extreme truck lube somewhere, is that synthetic?

I have been reading about proper lubricants for polymer acme screws from linear actuator companies (industrial not satellite) and I gather that polymer nuts either don't need any or recommend PTFE. So am a little baffled about everybody suggesting over greasing things and things oozing out - where exactly does it ooze out from ( only place is the base of the outer tube near the flange where it is screwed in. And wouldn't this block the water draining feature? So much conflicting information. Btw emails to Von WEise yielded no results yet if ever as they are out of the satellite game. Venture is hush hush about theirs - why the big secret? Probably don't want us repairing these for another 25 years, duh and nobody buying new ones - talk about throw away society.

I forgot to mention there was small pieces of plastic lodged in the slits when the nut came off, but the nut appears to be in tact - nothing broken from what I can tell - I will borrow another new one to compare.

I am not crazy about the tap and screw method as I doubt that arrangement can handle the load esp. if I go more east than the zenith satellite with that poor nut having to hold and pull that tremendous strain - unless I add the spring strain relief idea of yours.

Well I will let him take another crack at it before I completely give up and park it on one bird. In the meantime you've convinced me to clean off that copper compound and go with a standard synthetic grease. Where do people place the zerk? Odd this thing has been going for over a quarter century on hardly any grease if at all from the looks of it ( which corroborates what I read about polymer acme nuts, thin later of PTFE ( Teflon) that is then cured.

The poster who suggested getting a new actuator is probably shaking his head and cursing us poor cheap bastards right about now, hah. Wouldn't blame him if he was.

So what actually captures the nut in the tube? You said that you installed a new one, and that one got borked?

Yeah, time might be getting close for a new one but..since that time may be coming anyway why not give it a shot?

My set screw thing. You're doubtful. The tube looks thick enough to tap. Why not try it? How about 2 in the side of the tube. And a couple at the base of the nut to handle linear load? Rotational load would be taken care of because you would have the limit switches set for a safety margin.

I wouldn't sweat the little things. Grease. Moly definitely. Lucas red synthetic low temp too.

As for the zerk thing. 2 telescoping tubes. Extended. Put a grease fitting where you vision a blob pumped inside where the screw and nut would pick it up and distribute it along the screw. You might have to extend it again and pump another blob, then retract it again so the blob is spread around inside.

It looked like the units I have would be destroyed if I took them apart.

They were stiff and needed lubed. What were my options? Buy a new one?

Yeah, time might be getting close for a new one but..since that time may be coming anyway why not give it a shot?

My set screw thing. You're doubtful. The tube looks thick enough to tap. Why not try it? How about 2 in the side of the tube. And a couple at the base of the nut to handle linear load? Rotational load would be taken care of because you would have the limit switches set for a safety margin.

I wouldn't sweat the little things. Grease. Moly definitely. Lucas red synthetic low temp too.

As for the zerk thing. 2 telescoping tubes. Extended. Put a grease fitting where you vision a blob pumped inside where the screw and nut would pick it up and distribute it along the screw. You might have to extend it again and pump another blob, then retract it again so the blob is spread around inside.

It looked like the units I have would be destroyed if I took them apart.

They were stiff and needed lubed. What were my options? Buy a new one?

I contacted Von Wiese about six months ago and was informed they would not sell me the acme nut. There was a minimum order of 100 pieces FOB El Paso, TX.

I ordered a brass nut from Roton. There was something wrong with the way it was tapped since it would bind on the screw after about one turn. I was going to go to a machine shop to see what could be done but with all the closures I just ordered a tap from Fastenel and ran it through the brass nut. It took off a small amount and now it it screws on easily.

I did NOT cut the tabs. Instead I opted to hacksaw (actually used a reciprocating saw with the nut in a vice) to trim some off the sides of the nut and I drilled and tapped through the tabs and inserted a screw with Locktite and a lock washer. I haven't tested it yet because I think I will get some hard stainless steel screws instead of what I have in there now but I have no reason to believe it won't work just fine.

I ordered a brass nut from Roton. There was something wrong with the way it was tapped since it would bind on the screw after about one turn. I was going to go to a machine shop to see what could be done but with all the closures I just ordered a tap from Fastenel and ran it through the brass nut. It took off a small amount and now it it screws on easily.

I did NOT cut the tabs. Instead I opted to hacksaw (actually used a reciprocating saw with the nut in a vice) to trim some off the sides of the nut and I drilled and tapped through the tabs and inserted a screw with Locktite and a lock washer. I haven't tested it yet because I think I will get some hard stainless steel screws instead of what I have in there now but I have no reason to believe it won't work just fine.

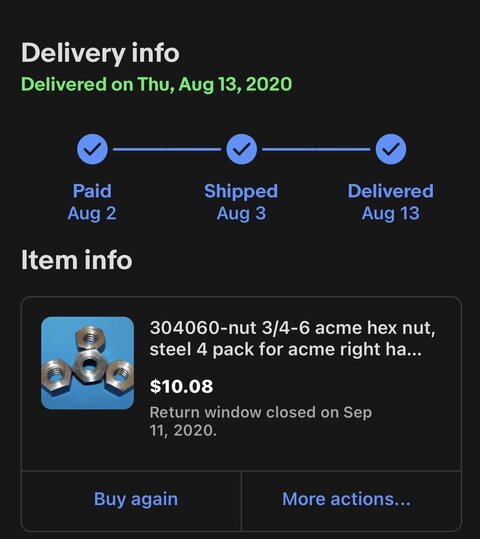

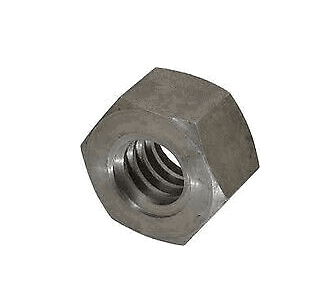

I want to share what I did with my Von Weise nut, I bought from ebay ¾-6 acme hex nut steel 4 pack, for $10.04, but I only used 2 nuts since it matched (wide enough to the oem plastic nut) and a friend of mine did some magic at his workshop, after that I have been using my von waise actuator for over 16 months over the arc from 40w to 133w with no issues, maybe is not the best option but is cheaper and works LOL.

Attachments

Nice mod!I want to share what I did with my Von Weise nut, I bought from ebay ¾-6 acme hex nut steel 4 pack, for $10.04, but I only used 2 nuts since it matched (wide enough to the oem plastic nut) and a friend of mine did some magic at his workshop, after that I have been using my von waise actuator for over 16 months over the arc from 40w to 133w with no issues, maybe is not the best option but is cheaper and works LOL.

Similar threads

- Replies

- 6

- Views

- 1K

- Replies

- 5

- Views

- 1K

- Replies

- 1

- Views

- 390

- Replies

- 13

- Views

- 1K