I'm researching what I need to do to get my 12' bud in the air and I want it done right. I've been studying info over at geo-orbit.org and it seems like I may very well be over-building things following the information there.

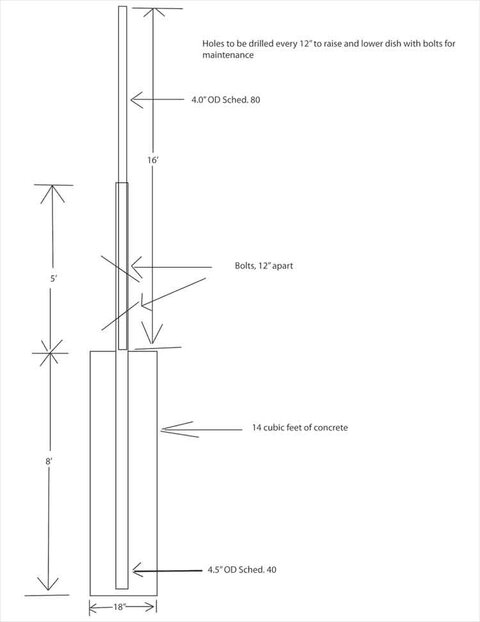

For LOS I need the mount 10' to 12' in the air. Geo-orbit suggests the pole be not less than 1/3 below grade, for 60" - 70" down. The hole should be not less than four times the diameter of the pole, for 16". The pole should not be less than schedule 80 due to the dish size. They also suggest that guys tied on at 30 degree angles will reduce or eliminate wind oscillation.

Due to the height and weight of this dish (200lbs give or take) I don't want to take the thing down should the worst happen and some Cat3 200kph storm hit, because it's nearly happened in the past.

Following that advice would I be under, about right, or over built?

For LOS I need the mount 10' to 12' in the air. Geo-orbit suggests the pole be not less than 1/3 below grade, for 60" - 70" down. The hole should be not less than four times the diameter of the pole, for 16". The pole should not be less than schedule 80 due to the dish size. They also suggest that guys tied on at 30 degree angles will reduce or eliminate wind oscillation.

Due to the height and weight of this dish (200lbs give or take) I don't want to take the thing down should the worst happen and some Cat3 200kph storm hit, because it's nearly happened in the past.

Following that advice would I be under, about right, or over built?