I recently went about reorganizing the 'dish farm' to consolidate dishes, add a Stab HH120 and eliminate some wiring runs and thought I'd share some photos.

My first dish, was placed on a 4x4 wooden post as it was my first foray into FTA and I didn't quite know what to expect. I used the wooden post and placed it in what I believed was the best spot to receive 125W. It stood this way from last July until just recently.

With all the recent rain, this mounting was becoming insufficient. I decided to move the dish to a more suitable mount in a different location. Before moving it, I went to swap out the Invacom LNBF for a Titanium PLL-Ku LNBF. As I was looking things over I found this, I'm sure it didn't help alignment any...

I believe they're mole pups, but not sure. With all the rain and saturated conditions, I guess it was too wet for them.

Over the course of a few weeks and between rains, I got one of the 1.2m dishes moved and motorized. When it came time to move the 1.2m from the wood post (which badly needing tuning), I swapped out LNBF's to make sure the new LNBF worked.

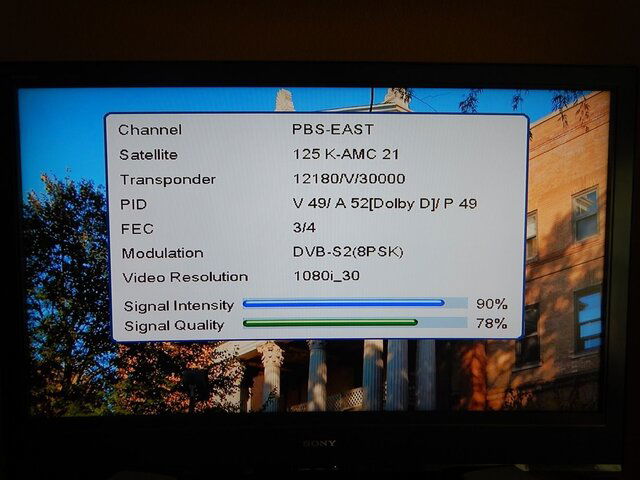

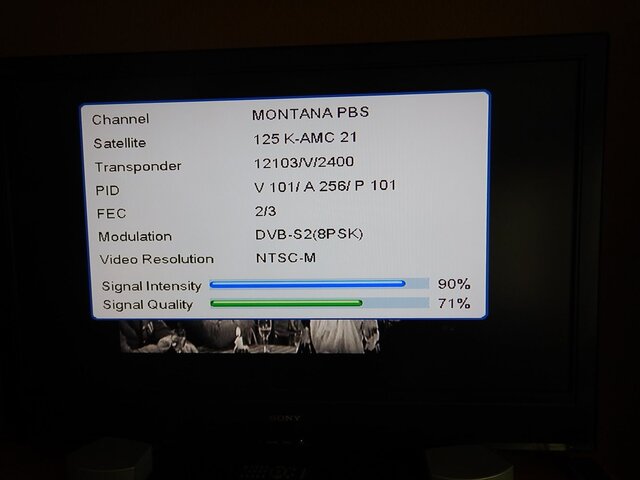

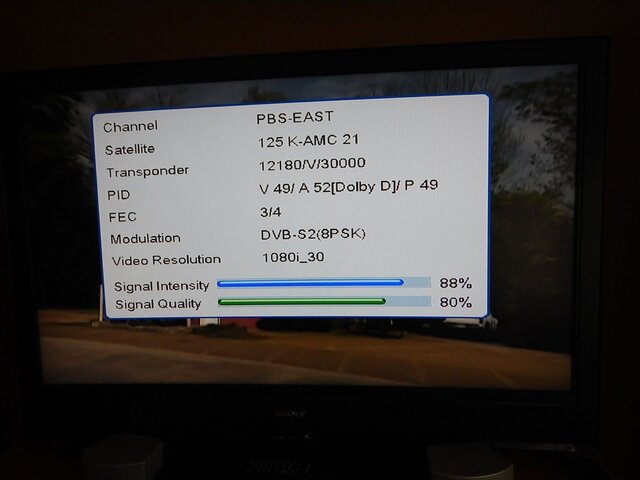

Before with the Invacom SNH-031:

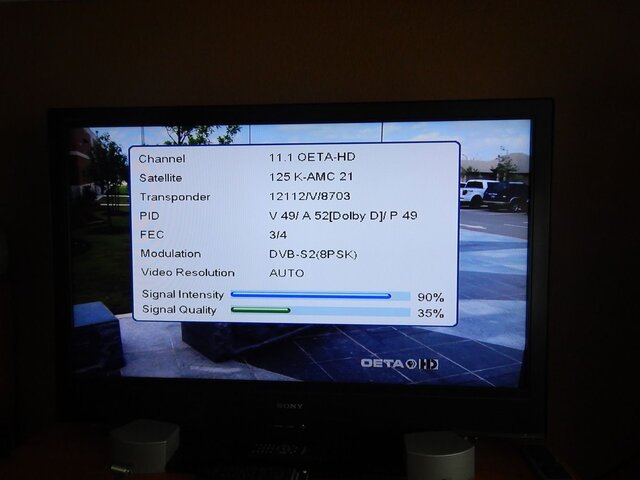

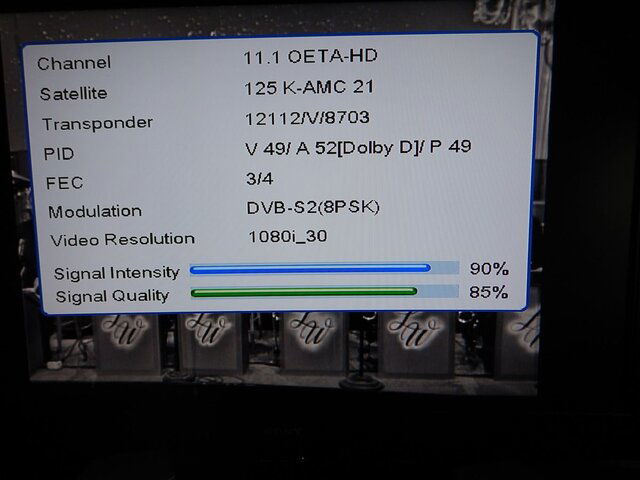

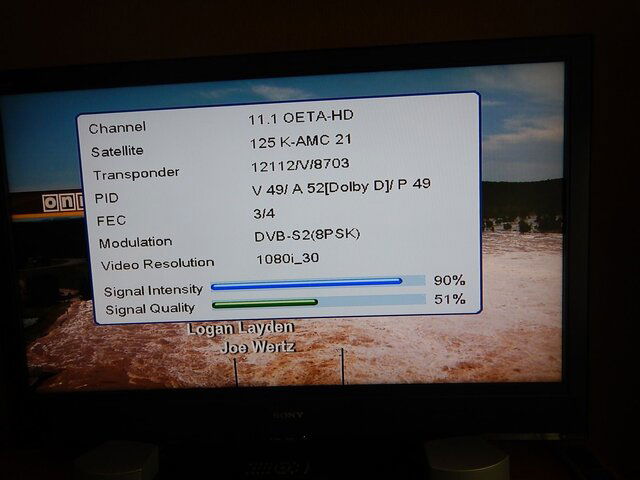

After with the Titanium PLL-Ku (and a poor skew adjustment):

To mount the two 1.2m dishes, I used 2 1/2" ID oil field pipe and had a welder weld 1/4" steel onto the bottom. I drilled a drain hole in the bottom mounting plate to allow condensation out. The new base would be rebar reinforced concrete with 1/2" J-bolts to attach the pipe and allow fine tuning for plumb.

I should've had the welder cap the tops, but didn't. For the dish with the Stab motor, a chainlink fence post cap fits snugly. For the fixed dish, I used styrafoam cut to about the right size and then secured a metal 'cap' using RTV. I figure it will work well enough to keep out critters.

For the concrete base on the two dishes. I dug the hole down to about 3 1/2-feet (then it's rock). The hole measured about 15-18" (E-W) by around 10" (N-S). The bottom was belled and then concrete placed in the bottom. I placed about a foot of mixed concrete in the hole added some more rebar to the bottom and then placed the cage with the J-bolts. I got the hole filled and double checked J-bolt spacing along the way. I let the concrete cure a week before mounting the pole.

So here is a closeup of the concrete base and pole mount. This is the second post, the first is similar.

About the time I was getting ready to move the second dish, I herd a mewing from across the street. I went to investigate and found this little furball...

There are quite a few stray cats in the area and the kitten appears to have been abandoned. The neighbors said it wasn't theirs and the kids liked her, so we brought her home and fed her. She's a very happy kitty now.

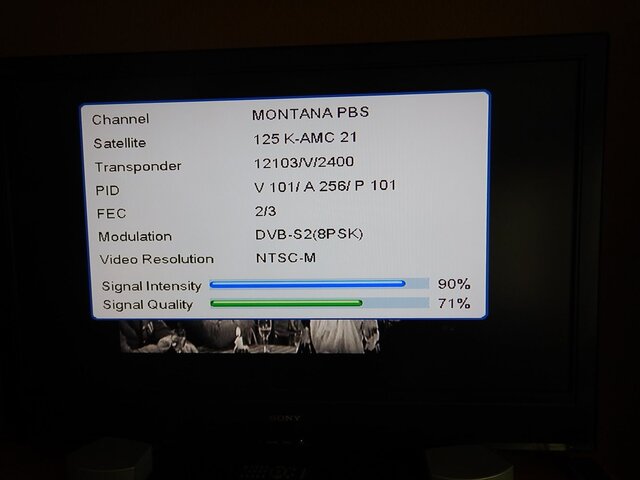

As for the dish that was on the wooden post, I got it set on 125W and locked. I then began work to peak the Q. I could only get about 74% on 12112 V 8703 and decided to add the plumbers strap to this dish as well.

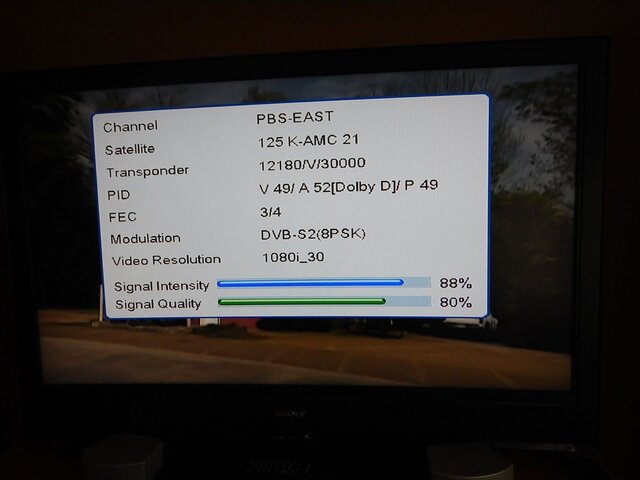

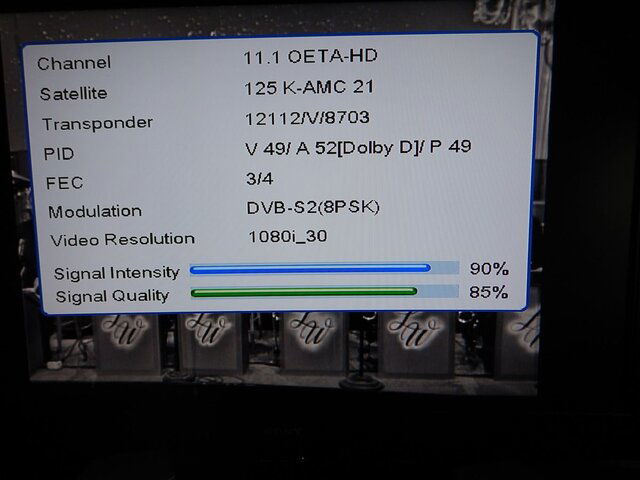

After a bit of tuning, I was pretty happy. Previously, I usually had 71-72% on this transponder. Here is an example of the regular new Q with the steel pole, PLL LNBF and dish reinforcement:

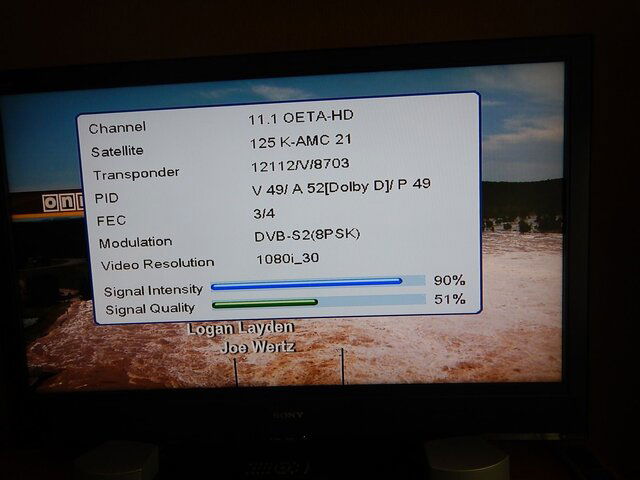

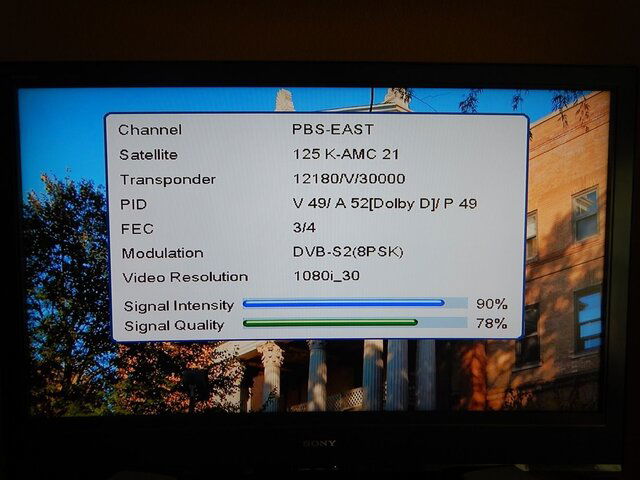

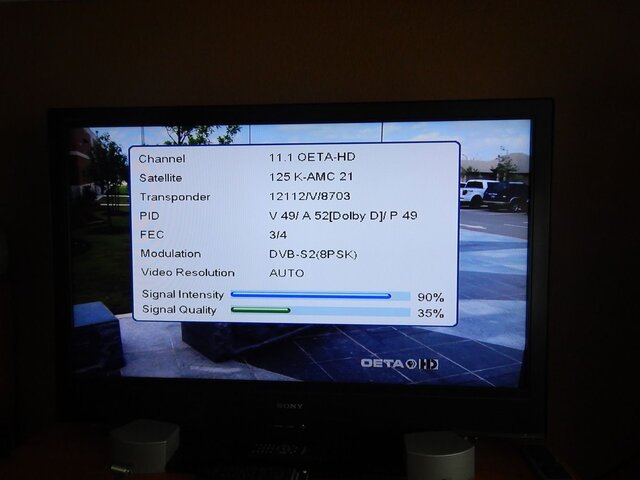

This is the other dish setup with the Stab HH120. I've got some more tinkering to do with this, if I'm going to keep the dish on this motor.

And finally, the newly organized and renovated setup :

My first dish, was placed on a 4x4 wooden post as it was my first foray into FTA and I didn't quite know what to expect. I used the wooden post and placed it in what I believed was the best spot to receive 125W. It stood this way from last July until just recently.

With all the recent rain, this mounting was becoming insufficient. I decided to move the dish to a more suitable mount in a different location. Before moving it, I went to swap out the Invacom LNBF for a Titanium PLL-Ku LNBF. As I was looking things over I found this, I'm sure it didn't help alignment any...

I believe they're mole pups, but not sure. With all the rain and saturated conditions, I guess it was too wet for them.

Over the course of a few weeks and between rains, I got one of the 1.2m dishes moved and motorized. When it came time to move the 1.2m from the wood post (which badly needing tuning), I swapped out LNBF's to make sure the new LNBF worked.

Before with the Invacom SNH-031:

After with the Titanium PLL-Ku (and a poor skew adjustment):

To mount the two 1.2m dishes, I used 2 1/2" ID oil field pipe and had a welder weld 1/4" steel onto the bottom. I drilled a drain hole in the bottom mounting plate to allow condensation out. The new base would be rebar reinforced concrete with 1/2" J-bolts to attach the pipe and allow fine tuning for plumb.

I should've had the welder cap the tops, but didn't. For the dish with the Stab motor, a chainlink fence post cap fits snugly. For the fixed dish, I used styrafoam cut to about the right size and then secured a metal 'cap' using RTV. I figure it will work well enough to keep out critters.

For the concrete base on the two dishes. I dug the hole down to about 3 1/2-feet (then it's rock). The hole measured about 15-18" (E-W) by around 10" (N-S). The bottom was belled and then concrete placed in the bottom. I placed about a foot of mixed concrete in the hole added some more rebar to the bottom and then placed the cage with the J-bolts. I got the hole filled and double checked J-bolt spacing along the way. I let the concrete cure a week before mounting the pole.

So here is a closeup of the concrete base and pole mount. This is the second post, the first is similar.

About the time I was getting ready to move the second dish, I herd a mewing from across the street. I went to investigate and found this little furball...

There are quite a few stray cats in the area and the kitten appears to have been abandoned. The neighbors said it wasn't theirs and the kids liked her, so we brought her home and fed her. She's a very happy kitty now.

As for the dish that was on the wooden post, I got it set on 125W and locked. I then began work to peak the Q. I could only get about 74% on 12112 V 8703 and decided to add the plumbers strap to this dish as well.

After a bit of tuning, I was pretty happy. Previously, I usually had 71-72% on this transponder. Here is an example of the regular new Q with the steel pole, PLL LNBF and dish reinforcement:

This is the other dish setup with the Stab HH120. I've got some more tinkering to do with this, if I'm going to keep the dish on this motor.

And finally, the newly organized and renovated setup :