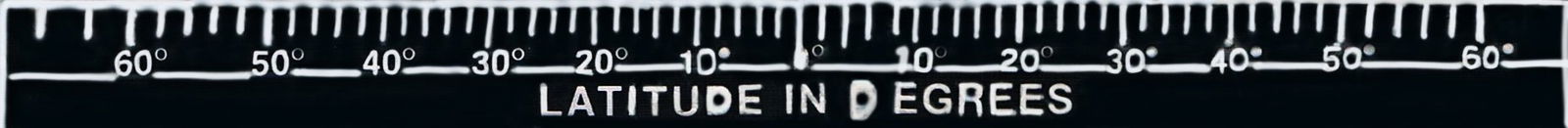

I think I got it- the dish structure centers on a hub that has a ~4" round pipe stub to insert into the ~4 1/4" round mount opening. The pipe stub on the dish is cut at a specific angle before it's welded to the center hub, thus when inserted into the mount receptacle the dish structure is free to "spin" on the mount, with a continuous up/down wobble. Wherever it's specifically stopped on the "spin" and the 2 set bolts in the mount receptacle tightened, that's the declination setting, and the mount receptacle (when new) had a declination scale with degree markings attached in form of an adhesive strip. The dish hub had a little white line in paint (maybe also an impression mark) to align to indicated latitude spec on the sticker. So the mount sticker would weather away and maybe also the hub marking, and if you need to reset declination what to do? For my part as I recall, I simply did a spin-around on the dish, observing the up & down change, guessed a spot basically in the middle, locked the set bolts and tried the arc. Peaking elevation straight south, I would start moving west. If getting noticably weaker signal, I'd check to see which way elevation would strengthen it, and then I'd know where to go back and adjust on declination. I'd be sure to leave the elevation where I had first set it, go back straight south, adjust the declination (loosen set bolts, slightly "spin" dish) to put the dish either slightly higher or lower according to what the more western arc needed, re-peak elevation (straight south) and then retry the arc.

Another facet of the dish's ability to "spin" on the mount was that it facilitated installation of the panel sections and retaining strips. Those would go in after the dish structure was fully assembled, the hub bolts tightened to rigidize it and the finished structure hoisted up into the mount. Also not having the panels in yet made for easy work to grab it by the ribs and perimeter to land the center stub pipe into the mount. Then just spin and put in panels. Easy 1-man job, and I was a 1-man band.