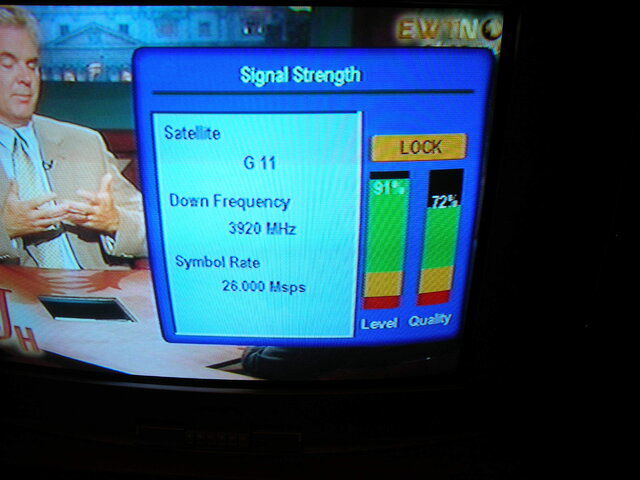

Back in May of this year, I got a C-band dish from Blindowl1234 in Ohio. Here is a series of photos of how it was disassembled and then moved to my location in Kentucky at my other location.

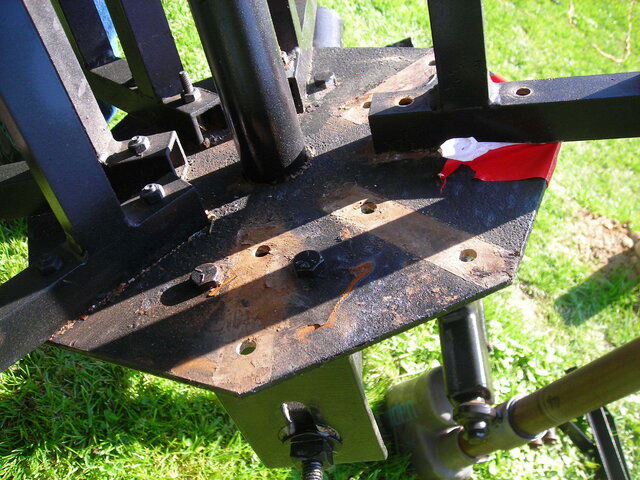

The dish when disassembled fits in the pickup truck with no problem. To take it down I used a cut off wheel , cut the mast and let it fall on its back then we disassembled it.

One of the hardest things involved in the process was finding a 3-1/2 inch metal post, forget Home Depot, Lowes and a scrap yard. I finally did locate one..with the concrete still on it. So I left the concrete on ...dug a hole to fit the concrete and post..(not easy to do in hard soil and high temp and humidity).

Filled it with concrete and then let it set, and painted the post. Put the brace over the post....then reassembled the dish and put the screening back on. Had to wait for help from my brother in law...then my brother in law, my wife and I were able to lift the dish on top of the brace.

For anyone thinking about moving a a C-band dish. A pick up truck, cut off saw, decent amount of tools, obtain a post (this might take some doing), cement, level to make post straight, time to disassemble and reassemble and most importantly at least three people to do the project . The reason why it took so long, I needed that third person to help lift the dish. Ideally...I think four or five people could disassemble, move and reassemble in a day or two (except the time for the concrete to set).

I could only post 10 pictures at a time...I will post the rest following this one...

.

The dish when disassembled fits in the pickup truck with no problem. To take it down I used a cut off wheel , cut the mast and let it fall on its back then we disassembled it.

One of the hardest things involved in the process was finding a 3-1/2 inch metal post, forget Home Depot, Lowes and a scrap yard. I finally did locate one..with the concrete still on it. So I left the concrete on ...dug a hole to fit the concrete and post..(not easy to do in hard soil and high temp and humidity).

Filled it with concrete and then let it set, and painted the post. Put the brace over the post....then reassembled the dish and put the screening back on. Had to wait for help from my brother in law...then my brother in law, my wife and I were able to lift the dish on top of the brace.

For anyone thinking about moving a a C-band dish. A pick up truck, cut off saw, decent amount of tools, obtain a post (this might take some doing), cement, level to make post straight, time to disassemble and reassemble and most importantly at least three people to do the project . The reason why it took so long, I needed that third person to help lift the dish. Ideally...I think four or five people could disassemble, move and reassemble in a day or two (except the time for the concrete to set).

I could only post 10 pictures at a time...I will post the rest following this one...

.

Attachments

-

C-Band-1.JPG1,016.1 KB · Views: 409

C-Band-1.JPG1,016.1 KB · Views: 409 -

C-Band-10.JPG1 MB · Views: 383

C-Band-10.JPG1 MB · Views: 383 -

C-Band-9.JPG699.1 KB · Views: 373

C-Band-9.JPG699.1 KB · Views: 373 -

C-Band-8.JPG974.9 KB · Views: 354

C-Band-8.JPG974.9 KB · Views: 354 -

C-Band-7.JPG994.6 KB · Views: 388

C-Band-7.JPG994.6 KB · Views: 388 -

C-Band-6.JPG789.8 KB · Views: 372

C-Band-6.JPG789.8 KB · Views: 372 -

C-Band-5.JPG986.1 KB · Views: 339

C-Band-5.JPG986.1 KB · Views: 339 -

C-Band-4.JPG703.9 KB · Views: 343

C-Band-4.JPG703.9 KB · Views: 343 -

C-Band-3.JPG940.6 KB · Views: 361

C-Band-3.JPG940.6 KB · Views: 361 -

C-Band-2.JPG951.5 KB · Views: 365

C-Band-2.JPG951.5 KB · Views: 365

Last edited: