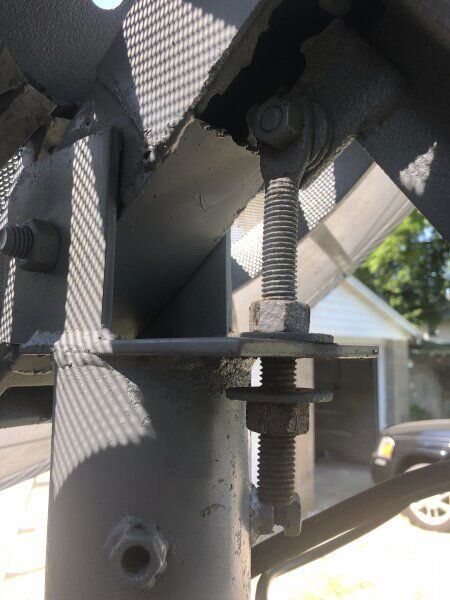

Clean the parts with rubbing alcohol, let dry and Super Glue (or my favorite, Epoxy) back together. Repaired many customers servo links with epoxy and the part would outlast the rest of the system!Good news the servo is fine bad news there a plastic piece the servo sits on that spins it that's broke. Do you think a dab of super glue would work?