Oh, good catch - use very thin layer of silicone grease, it would be easy to remove the foil after tests. I would make triangle pieces of the foil - gaps wouldn't blur focal spot, rather overlapping spots. Try to avoid make wrinkles.

fabricating a cband dish

- Thread starter jmc98

- Start date

- Latest activity Latest activity:

- Replies 58

- Views 12K

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Please reply by conversation.

like making sections of a BUD, I gotcha. I'll also take off the LNB, don't want to accidently fry it. This is getting interesting.

Before I took off the DTV LBNs I taped a string from the top of the dish taped it the center of the LNB and then taped it to the bottom of the dish. I made a black mark on the face of the string at the lnb. I took off the DTV LNBs and mounted a new holder and Ivacom LNB and adjusted it to the strings black mark. The setting worked great, but I did not know if it was the optimum setting, so today I drilled new holes in LNB mast spaced around 3/4 inches apart. I had around 3/4 inch adjustment on the neck of the lnb so I have abou 1 1/2 inches to make an adjustment. I was able to slide the LNB and holder up and down the mast and found that the LNB had a large range with out signal drop out. I actually remounted the the lnb 3/4 of inch further away from the reflector.

I also played around with placing my hand on sections of the reflector to see when I would lose the signal. the only tme I knocked out the signal was when I put my arm accross the center of the reflector. I love the hands on training I'm doing.

Before I took off the DTV LBNs I taped a string from the top of the dish taped it the center of the LNB and then taped it to the bottom of the dish. I made a black mark on the face of the string at the lnb. I took off the DTV LNBs and mounted a new holder and Ivacom LNB and adjusted it to the strings black mark. The setting worked great, but I did not know if it was the optimum setting, so today I drilled new holes in LNB mast spaced around 3/4 inches apart. I had around 3/4 inch adjustment on the neck of the lnb so I have abou 1 1/2 inches to make an adjustment. I was able to slide the LNB and holder up and down the mast and found that the LNB had a large range with out signal drop out. I actually remounted the the lnb 3/4 of inch further away from the reflector.

I also played around with placing my hand on sections of the reflector to see when I would lose the signal. the only tme I knocked out the signal was when I put my arm accross the center of the reflector. I love the hands on training I'm doing.

What meter you're using ? I would recommend some FTA receiver what split SQ an SS; so pay more attention to SQ.

What meter you're using ? I would recommend some FTA receiver what split SQ an SS; so pay more attention to SQ.

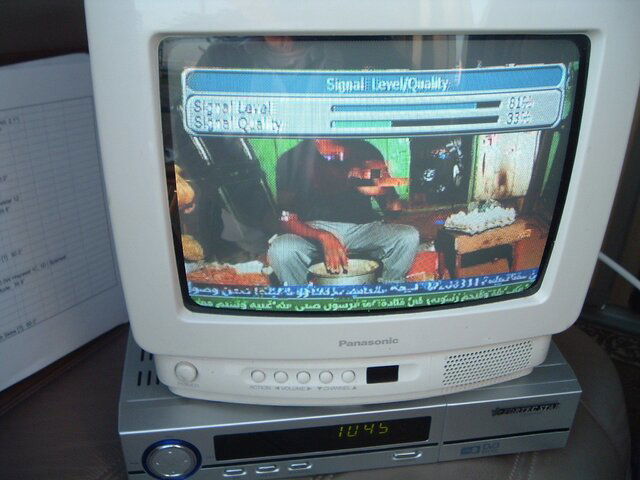

I'm using A Fortec Star Dynamic receiver. The remote has a sig button when you press it it appears at the top of the screen with a signal strength and signal quality meter. What's great is comes on top of the picture so if you are are adjusting the dish you can monitor the picture, sound and use the meters.

Here are pic's of my test set up.

Attachments

I'd like your test bed - a level (two ?), fine tuning screws (!), ball bearing plate ...

BUT ! SQ is too low, looks like f/d of your LNBF is way out of the dish capabilities, plus a size perhaps small for FTA BSS sats.

What sat is it ? Tpn ?

BUT ! SQ is too low, looks like f/d of your LNBF is way out of the dish capabilities, plus a size perhaps small for FTA BSS sats.

What sat is it ? Tpn ?

That is Atlantic Bird 2, check out the last thread in this post:

http://www.satelliteguys.us/free-air-fta-discussion/174503-atlantic-bird-2-a.html

http://www.satelliteguys.us/free-air-fta-discussion/174503-atlantic-bird-2-a.html

Yes I get the... Focal Point!

Well, guys, the weather was sunny and I had time, aluminum foil and the wife to take the pictures.

I place the foil over a Dtv 18 x 20 inch dish and illuminated the dish with the full noon sun. I held a black piece of plastic at the focal point and Yes there is a visible focal point that can be seen. A lesson well learned thanks Mr. Smith.

Mr. Smith there was one thing that you forgot to tell me, that is, wear sunglasses. LOL :up

Oh, good catch - use very thin layer of silicone grease, it would be easy to remove the foil after tests. I would make triangle pieces of the foil - gaps wouldn't blur focal spot, rather overlapping spots. Try to avoid make wrinkles.

Well, guys, the weather was sunny and I had time, aluminum foil and the wife to take the pictures.

I place the foil over a Dtv 18 x 20 inch dish and illuminated the dish with the full noon sun. I held a black piece of plastic at the focal point and Yes there is a visible focal point that can be seen. A lesson well learned thanks Mr. Smith.

Mr. Smith there was one thing that you forgot to tell me, that is, wear sunglasses. LOL :up

Attachments

Fabbing your own dish

It may at first glance seem stupid to want to build your own dish. But how do you think people learn? I remember seeing an article in an early Popular Science about building a dish back in the 1960's (when only NASA owned them).

Any old ditch digger can go dig one up for free in somebody's back yard. I'm fifty-five and still interested in Atwater Kent radios (circa 1928) and crystal radios (circa 1910). Antique electronics is still amazing to me. How did they do all that stuff with oatmeal boxes and wire?

I think the knowledge gained would be invaluable to anyone. I (for one) am rooting for the guy who wants to build one from nothing. Go for it! :

: :

: :

:

It may at first glance seem stupid to want to build your own dish. But how do you think people learn? I remember seeing an article in an early Popular Science about building a dish back in the 1960's (when only NASA owned them).

Any old ditch digger can go dig one up for free in somebody's back yard. I'm fifty-five and still interested in Atwater Kent radios (circa 1928) and crystal radios (circa 1910). Antique electronics is still amazing to me. How did they do all that stuff with oatmeal boxes and wire?

I think the knowledge gained would be invaluable to anyone. I (for one) am rooting for the guy who wants to build one from nothing. Go for it!

:

: :

: :

:Looks like the spot size is double of LNBF throat.

The Dish is oval and had a three pack of DSS LNB mounted in the front. I was under the impression that an oval offset dish was designed this way. That is to have a wider focal point. I read that the dish is an ellipse and it is a section of a lager parabola. The arm would be the center of parabola. I use a Chapparral Universal LNB were the screw holds are and there is a large area to move it around without losing signal. This dish performs very well for its size.

I have a 90cm mounted on tripod that I bring in and out of the garage when the urge for FTA strikes. The dish is cheaply made and easily deformed with very disappointing results. I expected higher signal levels; some times the small DTV dish gives better SQ. I don't have a satellite store around my area so that you can go and look at the dishes to see which ones are constructed well. I am looking to replace the DTV dish test bed and use a Dish network 500 dish for a tester. I have been checking the local papers and Craig's list to see if I can come across one.

Now how would figure out with math where the focal point of the dish is?

Thanks again for the information on the experiment.

I'm using portable spectrum analyzer (Avcom PSA-37D) for that.

For your target when the dishes is in mass production, it would be easy to measure focal point location by taken a position of existing LNBF(s) on fully assembled one, like D500.

[If you need the D500, I have a few].

For your target when the dishes is in mass production, it would be easy to measure focal point location by taken a position of existing LNBF(s) on fully assembled one, like D500.

[If you need the D500, I have a few].

finding focal point:

This post refers to several methods of locating the focal point.

When swapping out LNBs on an existing dish, the template method is very useful.

This post refers to several methods of locating the focal point.

When swapping out LNBs on an existing dish, the template method is very useful.

I'm using portable spectrum analyzer (Avcom PSA-37D) for that.

For your target when the dishes is in mass production, it would be easy to measure focal point location by taken a position of existing LNBF(s) on fully assembled one, like D500.

[If you need the D500, I have a few].

I checked out the spectrum analyzer online and I took it that you work in the industry, as the unit was a little pricey for the average hobbyist. Do you have to have a satellite signal locked in to do the dish adjustments? Is there a signal generator that you can use to point at the dish to do the dish alignment?

I might take you up on that offer for a DN 500 dish my DTV one has a strip tilt screw. I am working on making up a new test board. I left the one I had out in the rain and the fiberboard has distorted and warped. I have been scouring Home Depot and Lowes for parts.

I have been thinking about that sun measurement test and your statement that the spot was double the LNBF throat size. Did I do the measurement wrong should I moved the paper back further from the dish?Looks like the spot size is double of LNBF throat.

I would play with the distance just to see how the spot size changing.

No, no lock require for initial aiming, if you remember the pattern, you could recognize a sat by SA screen picture. This SA have own minus, since the design came from analog era. It cannot measure SNR, so maxing SS level not always giving you best SQ, so after initial set better to connect a receiver and tune to highest SQ or better SNR.

No, no lock require for initial aiming, if you remember the pattern, you could recognize a sat by SA screen picture. This SA have own minus, since the design came from analog era. It cannot measure SNR, so maxing SS level not always giving you best SQ, so after initial set better to connect a receiver and tune to highest SQ or better SNR.

here i found a homemade dish on the forum pretty cool

http://www.satelliteguys.us/free-ai...-build-your-own-cardboard-satellite-dish.html

john

http://www.satelliteguys.us/free-ai...-build-your-own-cardboard-satellite-dish.html

john

I would play with the distance just to see how the spot size changing.

No, no lock require for initial aiming, if you remember the pattern, you could recognize a sat by SA screen picture. This SA have own minus, since the design came from analog era. It cannot measure SNR, so maxing SS level not always giving you best SQ, so after initial set better to connect a receiver and tune to highest SQ or better SNR.

Do the newer type digital meters work better?? I was looking to pickup a used Birddog on E-Bay for a couple of hundred bucks. So were a lot of other folks most of the bids were over two hundred bucks.

That sun focal point experiment had me thinking.

I read that the stamping of the dish reflectors only produced about 50 percent efficiency. Now that I know that dish focal point can be measure, by light it would not be hard to aim a know quantity of light at the dish and measure it intensity at the focal point. It looks like to me the dish reflectors that are manufactured can be stamped and tuned to increase their efficiency.

......I read that the stamping of the dish reflectors only produced about 50 percent efficiency......looks like to me the dish reflectors that are manufactured can be stamped and tuned to increase their efficiency......

The 50% efficiency figure was a nominal figure chosen by Engineers in the industry before the Chinese and Koreans took over the market. Today, most manufacturers claim 75% efficiency. Lots of factors go into the overall gain (or efficiency) that the dish provides.

Materials of construction and manufacturing processes vary between dish manufacturers. A Birdview is a prime example. Although smaller in size, they perform better than much larger dishes because they were manufactured using a process that produced an accurate parabolic surface that could be repeated on every dish that was made.

- Status

- Please reply by conversation.

Similar threads

- Replies

- 37

- Views

- 4K

- Replies

- 0

- Views

- 539

- Replies

- 5

- Views

- 2K

- Replies

- 8

- Views

- 1K