Well the calculations are correct. If the measurements are also correct you have a F/D ratio of 3.4 (deep dish). The only reason I questioned it is because it was packaged in a KTI carton (maybe repackaged). Skyvision has a lot of new old stock parts for Cband dishes, feed support legs, polar mounts etc. They may have something for you. Personally there is so much programing available on Cband, I couldn't pick one bird for a fixed dish.

http://www.skyvision.com/pages/parts1.html

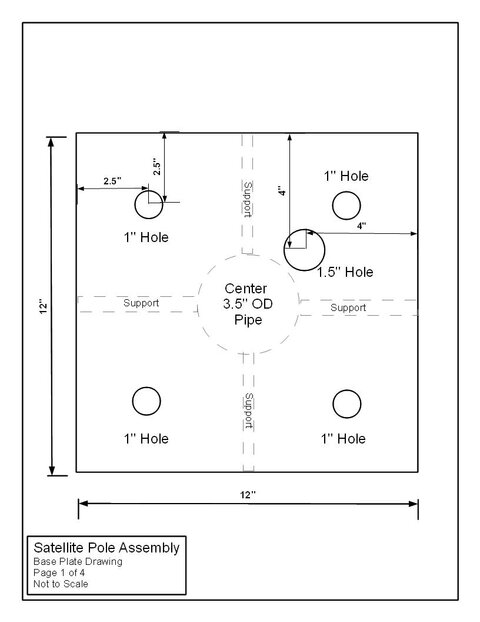

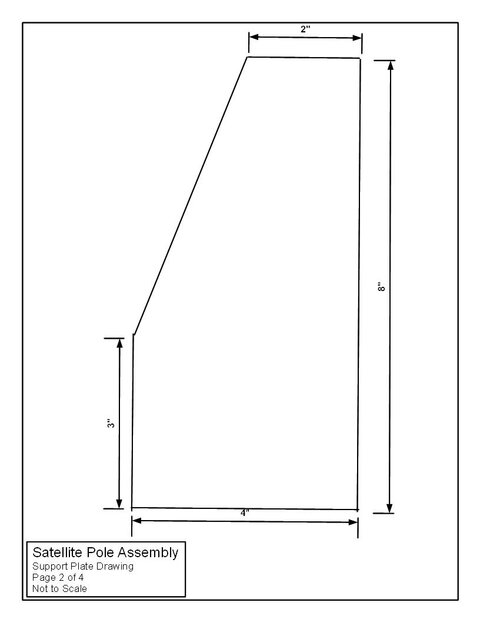

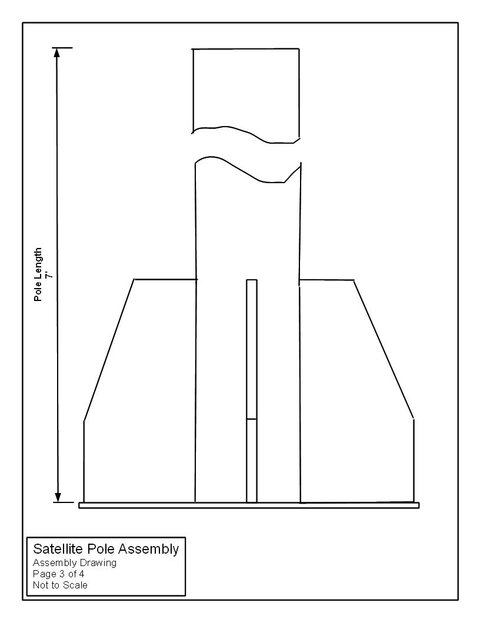

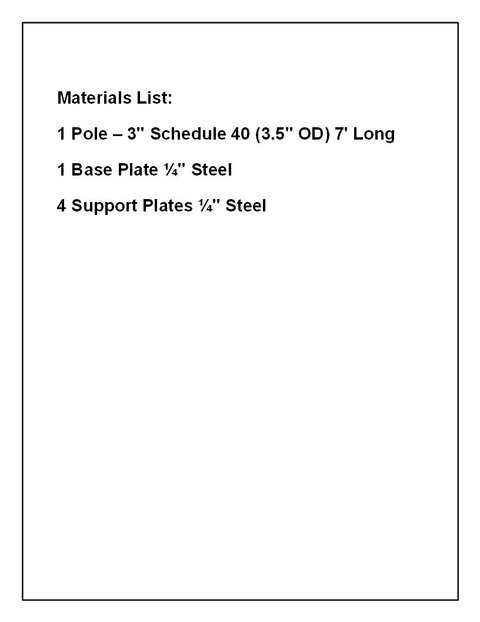

As far as your idea of fabricating a mounting plate goes, its is an excellent idea if you are up to the task. My Paraclipse classic 12 has one of those. It uses three nylon jackscrews to adjust focal distance . In this way you can adjust your F/D ratio independently from your focal distance (as well as centering your focal point on the dish). That makes a big difference when tuning for week signals (and for Ku reception if you chose that option). If you are interested, I can PM you an illustration from my manual.