I'll pipe in. First. Good photos of your current setup will help a lot.

You should also state the sensor type you might currently use. Reed, hall, optical, potentiometer?

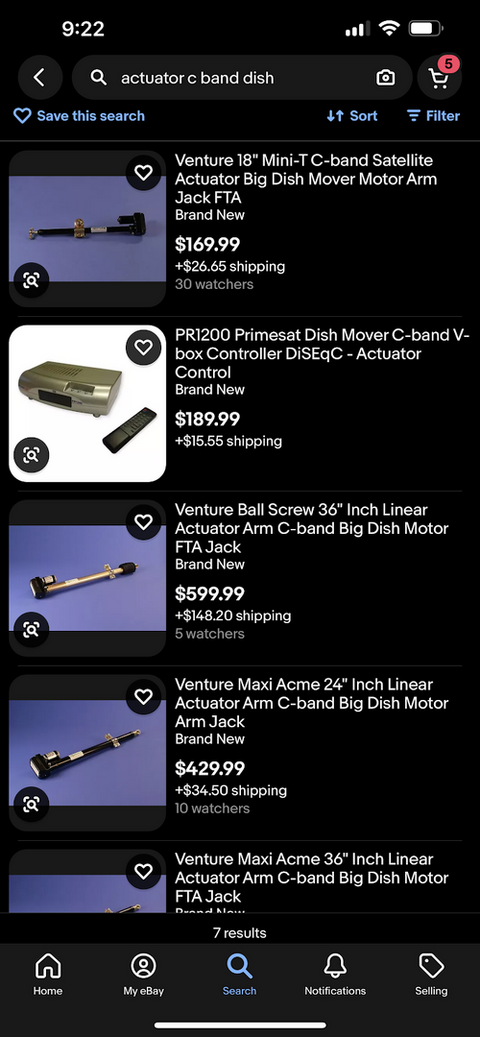

And. Skimping on actuator quality will only exercise the disposable income concept. AKA: buy once, cry once.

Not saying that the most expensive one out there is what everyone should buy. The typical chinesium knockoffs will only wear out in a short time. And if you're not crafty enough to tear one down for periodic maintenance to keep them living. Well.....ca-ching!

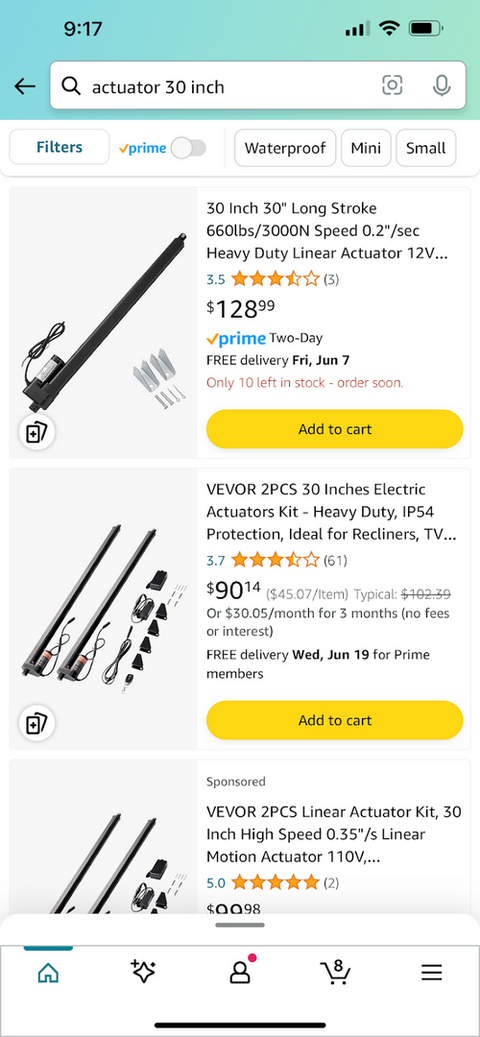

As far as the length of extension. It depends on your dish geometry and how an actuator can be mounted on it.

18" is very short. Perhaps for a small dish that weighs not much with a pivot mount that is close to the rotating axis.

24" seems to be the minimum norm. from what I see.

You could put your dish manually (with help or ratchet straps, etc.) and then run it through your intended arc and measure the extension needed.

One that is too short ($$$) will leave you wanting. One just right or too long will still let you swing the arc.

Slap up some photos. And be realistic. Can you really afford a cheap actuator? And are you subjected to nasty winters?