If you decide to put in a fine-tuning screw to adjust elevation, it would be nice to estimate how many turns per degree it gives you.

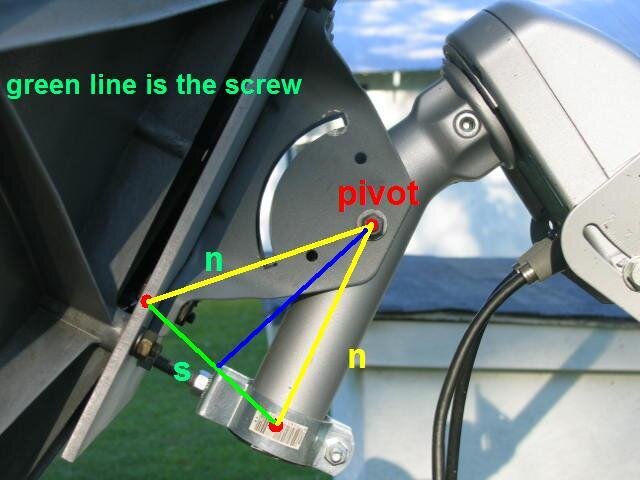

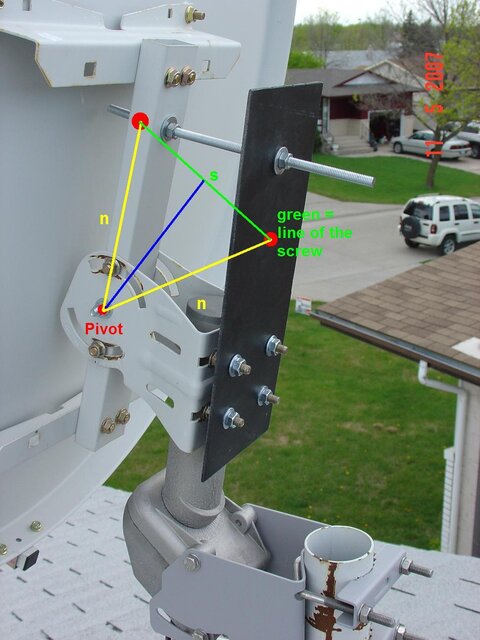

Shown, are two recent designs from some of our more industrious members.

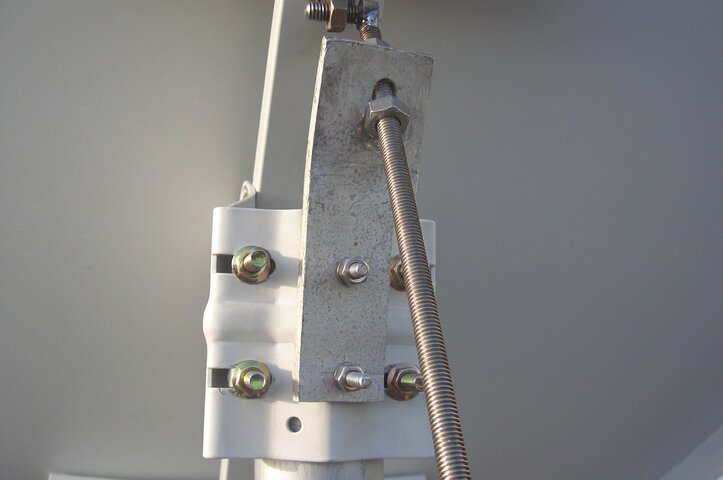

They use a tuning bolt, or a piece of all thread rod.

Since I don't have the actual numbers from the members who made them, I'll have to guess.

The same idea applies to adjusting the elevation or declination on C-band dishes, if you have the dimensions and do the math right.

There are several ways to skin this cat.

Biggest problem is making a generalized table which won't apply exactly to your situation.

However, the table below is a fair approximation, and should be good enough, so long as...

... the distance from the pivot to the screw is several times longer than the screw distance.

The actual math is:

sin-1(0.5s/n) X 2 = i

i / tpi = t

Shown, are two recent designs from some of our more industrious members.

They use a tuning bolt, or a piece of all thread rod.

Since I don't have the actual numbers from the members who made them, I'll have to guess.

The same idea applies to adjusting the elevation or declination on C-band dishes, if you have the dimensions and do the math right.

There are several ways to skin this cat.

Biggest problem is making a generalized table which won't apply exactly to your situation.

However, the table below is a fair approximation, and should be good enough, so long as...

... the distance from the pivot to the screw is several times longer than the screw distance.

Code:

[FONT=Courier New]n = distance of pivot bolt to adjustment screw

s = distance of the screw (assumed to be 1 for this table)

i = degrees movement per inch of screw travel

t = degrees movement per turn, given 20 turns per inch screw

tpi = turns per inch

T/º = Turns to go one degree, approx

n i t T/º

--- ---- ---- -----

2 30º 1.50º

3 19.5º 0.97º 1T/º

4 14.5º 0.72º

5 11.5º 0.57º

6 9.6º 0.48º 2T/º

7 8.2º 0.41º

8 7.2º 0.36º

9 6.4º 0.32º 3T/º

10 5.7º 0.286º

11 5.1º 0.26º 4T/º

---------------------[/FONT]sin-1(0.5s/n) X 2 = i

i / tpi = t