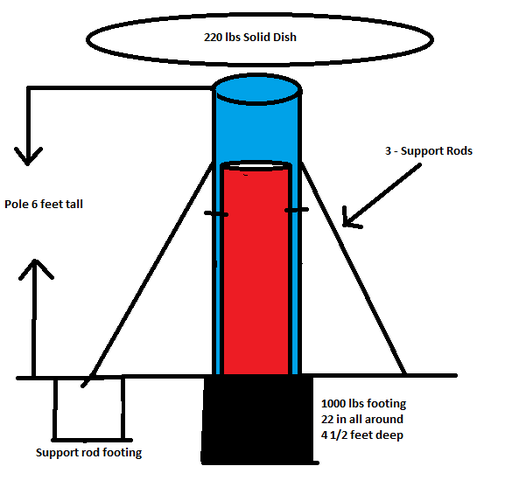

Post od is typical 3.5". I would not put a post over a post, that thing grabs all the wind that passes it.

post is 6' out of ground and lamp post set in about 7 wheelbarrels of concrete homebrew with test cylinder concrete (7000 psi break strength) making up support on walls surrounded by boulders up to 5' in diameter on the worst rocky ground in PA . Some rebar from work made a nice cage for in the crete. Used the cat 953 to dig out a large rock that made up the hole for the post The bolts are not visible because there is a small concrete cover over them. post is 6ft out of ground is so i can brush hog around that area and tractor tire just fits under dish at 107w.

The bolts are not visible because there is a small concrete cover over them. post is 6ft out of ground is so i can brush hog around that area and tractor tire just fits under dish at 107w.

It is doubtful that the bracket for the actuator mount to dish is original.

some day, she wil get a paint job.

post is 6' out of ground and lamp post set in about 7 wheelbarrels of concrete homebrew with test cylinder concrete (7000 psi break strength) making up support on walls surrounded by boulders up to 5' in diameter on the worst rocky ground in PA . Some rebar from work made a nice cage for in the crete. Used the cat 953 to dig out a large rock that made up the hole for the post

It is doubtful that the bracket for the actuator mount to dish is original.

some day, she wil get a paint job.

Attachments

Last edited: