I modified a few H2H 36 V motors so they can be controlled by Usals .

Its nessesary to generate approx. 40 pulses / 1º movement of the dish , therefore you have to change the reedswitch for a optical pulser .

The motor of a FIBO 120 cm Gregorian already was provide with such pulser with only 1 hole in the pulswheel , but to be exact for Usals it should be 6 and a half .

Far from exact but by changing the Latitude in the Usals menu to a more North position it workt fine with 6 holes .

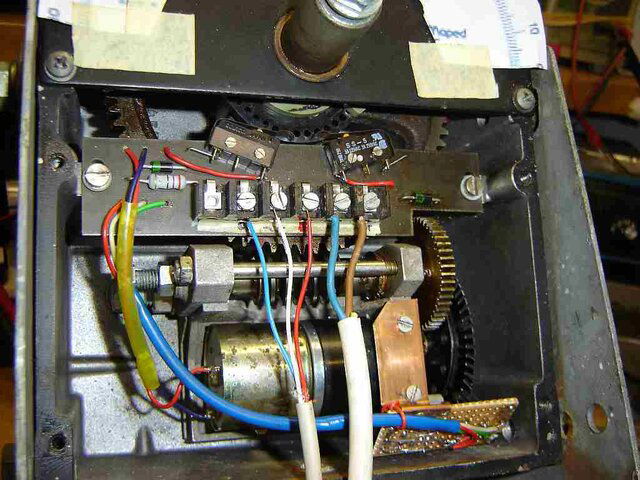

I used a old Clearmax CX2200 positioner , built the circuitboard of a SG2100 to it and used the east/west relays and the transformer .

This transformer produce also 12 volt ( most V-Boxes do also) and so i added a switch to have the choice between 36 and 12 volt to steer the motor (less noisy and exact)

By the lack of the SG2100 zero and end-switches you cant use the "Go to reference" command . Therefore you must steer the motor manual .

With the east and west switches on the front , it is possible to steer the motor without any effect to the memory of Usals .

Also did the job with a RM120 wich i have 2 , one with reedswitch , the other optical with a 10 hole wheel wich should be 66 holes .

Impossible to dril 66 holes to the edge of a 40 mm dia wheel , the space in the housing of that RM120 allowed a increase to 60 mm, still tricky , so i made 66 slots of 2 mm .

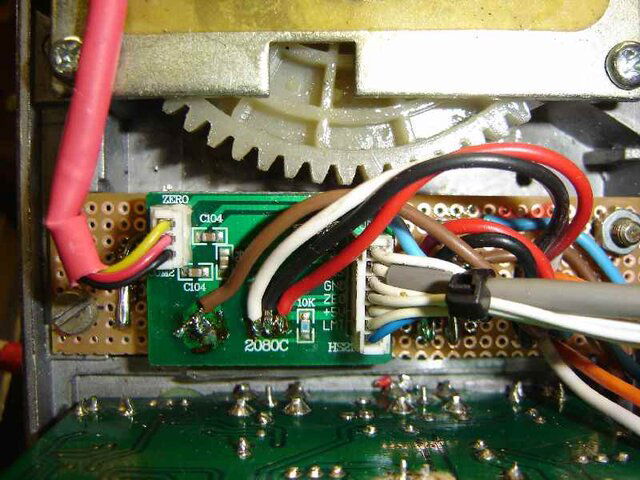

I attached a SG2100 without the worm-shaft and motor on top of the RM120 to make use of the zero and end-switches and the "Go to reference" command .

Removing the worm-shaft and motor , gives space for the contactor-interface , powered by a 30 V printer adapter .

Last job is a AJAK Horizon 180 , it has a reedswitch to a 5 magnet wheel , attaching a hood of a 50 mm pvc drainpipe with 48 slots to that wheel , was exactly the need for my latitude .

To determine the correct amount of pulses i attached a printed protractor to the rotor and by making use of a separate puls counter and turn the rotor 10º

By using GAAPS , a calculator of Moteck , its possible to see on the degree scale how far the rotor turns at a diseqc command .

Its nessesary to generate approx. 40 pulses / 1º movement of the dish , therefore you have to change the reedswitch for a optical pulser .

The motor of a FIBO 120 cm Gregorian already was provide with such pulser with only 1 hole in the pulswheel , but to be exact for Usals it should be 6 and a half .

Far from exact but by changing the Latitude in the Usals menu to a more North position it workt fine with 6 holes .

I used a old Clearmax CX2200 positioner , built the circuitboard of a SG2100 to it and used the east/west relays and the transformer .

This transformer produce also 12 volt ( most V-Boxes do also) and so i added a switch to have the choice between 36 and 12 volt to steer the motor (less noisy and exact)

By the lack of the SG2100 zero and end-switches you cant use the "Go to reference" command . Therefore you must steer the motor manual .

With the east and west switches on the front , it is possible to steer the motor without any effect to the memory of Usals .

Also did the job with a RM120 wich i have 2 , one with reedswitch , the other optical with a 10 hole wheel wich should be 66 holes .

Impossible to dril 66 holes to the edge of a 40 mm dia wheel , the space in the housing of that RM120 allowed a increase to 60 mm, still tricky , so i made 66 slots of 2 mm .

I attached a SG2100 without the worm-shaft and motor on top of the RM120 to make use of the zero and end-switches and the "Go to reference" command .

Removing the worm-shaft and motor , gives space for the contactor-interface , powered by a 30 V printer adapter .

Last job is a AJAK Horizon 180 , it has a reedswitch to a 5 magnet wheel , attaching a hood of a 50 mm pvc drainpipe with 48 slots to that wheel , was exactly the need for my latitude .

To determine the correct amount of pulses i attached a printed protractor to the rotor and by making use of a separate puls counter and turn the rotor 10º

By using GAAPS , a calculator of Moteck , its possible to see on the degree scale how far the rotor turns at a diseqc command .

Attachments

-

Degree scale.jpg48 KB · Views: 929

Degree scale.jpg48 KB · Views: 929 -

48 pulswheel.jpg49.3 KB · Views: 1,052

48 pulswheel.jpg49.3 KB · Views: 1,052 -

Ajak org. 5 magnet pulswheel.jpg49 KB · Views: 1,089

Ajak org. 5 magnet pulswheel.jpg49 KB · Views: 1,089 -

Pulser housing.jpg49 KB · Views: 829

Pulser housing.jpg49 KB · Views: 829 -

usals modif.jpg41.8 KB · Views: 1,670

usals modif.jpg41.8 KB · Views: 1,670 -

Pulser housing inside.jpg48.9 KB · Views: 886

Pulser housing inside.jpg48.9 KB · Views: 886 -

RM120 usals.jpg48.7 KB · Views: 1,276

RM120 usals.jpg48.7 KB · Views: 1,276 -

contactor interface in SG2100.jpg48.7 KB · Views: 889

contactor interface in SG2100.jpg48.7 KB · Views: 889

Last edited: