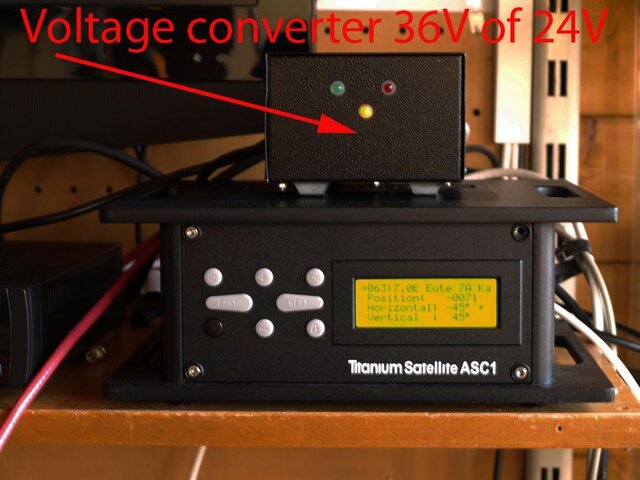

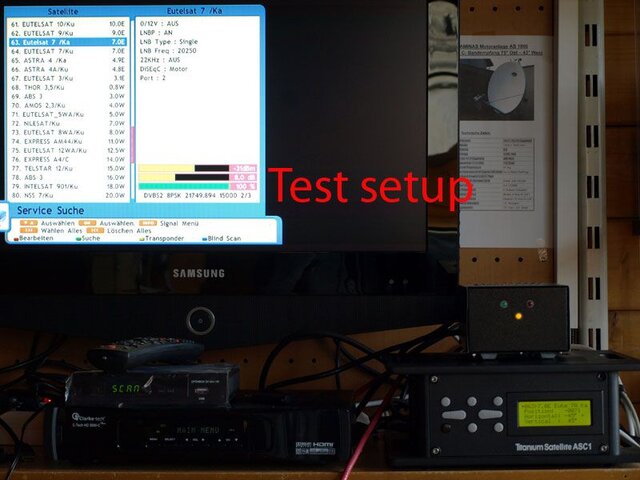

Did the latest update on my main ASC1. Worked well. Actually added another step to make sure all was ok... hadn't done an upload to the ASC1 for quite a while (last update?), so I transferred the user data to the laptop using V 1.8 loader, reset the ASC1 memory, then uploaded the saved file back to the ASC1 to make sure the data would be read properly.

After doing the firmware update, the user data was transferred using the 2.0 updater. Unit seems to work fine.

Thanks Brian for the very detailed instructions and the update!

Now time to update my backup unit!

After doing the firmware update, the user data was transferred using the 2.0 updater. Unit seems to work fine.

Thanks Brian for the very detailed instructions and the update!

Now time to update my backup unit!